Cardboard cutters are widely used in the packaging and printing industry for processing corrugated board, gray board, honeycomb board, and other packaging materials. To ensure their long-term stability, high efficiency, and precise cutting performance, regular maintenance and upkeep are essential.

In this article, we will explain the most important maintenance measures for cardboard cutters and why they matter for your business.

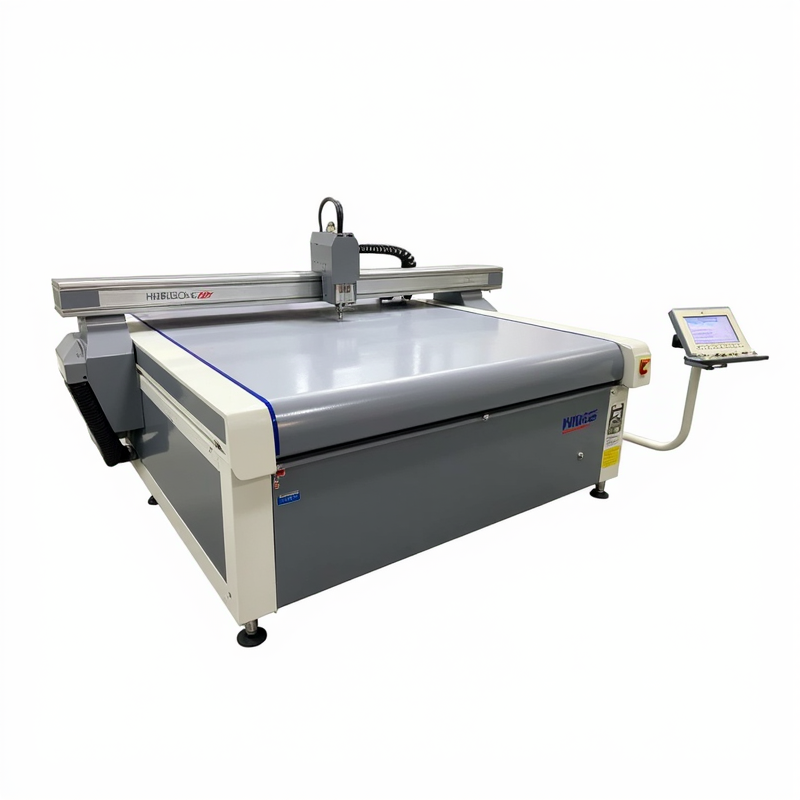

What Is a Cardboard Cutter?

A cardboard cutter (also called a cardboard packaging cutting tool or CNC cardboard cutting machine) is specialized equipment designed to cut paperboard, corrugated board, foam board, and similar materials.

It is commonly used in:

-

Packaging factories (carton boxes, protective packaging)

-

Display & advertising industry (POP displays, exhibition props)

-

Furniture and logistics (honeycomb cardboard supports)

Like all CNC equipment, cardboard cutters combine mechanical precision with software control. But to keep them running at peak performance, systematic maintenance is required.

Common Maintenance Measures for Cardboard Cutters

1. Regular Cleaning

Keeping the machine clean is the first step in proper maintenance.

-

Remove dust, paper scraps, and debris from the surface and inside of the machine.

-

Pay special attention to the cutting blade and cutting area, ensuring they remain free of residue.

-

Regular cleaning ensures cutting quality and extends the tool life.

2. Lubrication and Mechanical Maintenance

The moving parts of a cardboard cutter experience constant friction.

-

Check and apply lubricating oil to gears, bearings, and sliding rails.

-

Replace old or contaminated lubricants on schedule.

-

Proper lubrication reduces wear, prevents overheating, and extends the service life of the machine.

3. Knife and Tool Maintenance

The cutting tool is the core component of the machine.

-

Inspect blades frequently for wear and damage.

-

Replace heavily worn blades promptly.

-

Perform grinding and dressing of cutting tools to restore sharpness and maintain accurate geometry.

-

Regular tool care guarantees cutting precision and lowers overall operating costs.

4. Electrical System Inspection

A stable electrical system is key to safe and reliable machine performance.

-

Inspect cables, connectors, and terminals for loose or damaged parts.

-

Test switches, fuses, and relays to ensure functionality.

-

Replace aging or faulty components immediately.

This helps prevent unexpected downtime and ensures safe operation.

5. Safety Equipment Testing

Safety is non-negotiable in industrial production.

-

Check the condition of safety guards, emergency stop buttons, and sensors.

-

Repair or replace damaged safety equipment promptly.

-

Ensuring these systems are fully functional protects both operators and equipment.

6. Frame Structure Inspection

The frame is the foundation of the entire machine.

-

Inspect for signs of deformation, cracks, or instability.

-

Reinforce or repair abnormal parts immediately.

-

A solid frame ensures stable cutting and reduces machine vibration.

7. Operator Training and Specifications

Even with a well-maintained machine, improper operation can cause failures.

-

Provide regular training on operating procedures and safety standards.

-

Ensure operators understand the machine’s working principles.

-

Standardized operation minimizes mistakes and accidents.

Why Maintenance Matters for Your Business

Through scientific and effective maintenance measures, cardboard cutters can achieve:

-

Consistent cutting quality

-

Reduced downtime and repair costs

-

Extended machine lifespan

-

Higher production efficiency

-

Improved operator safety

For packaging factories and printing companies, this translates directly into higher productivity and lower costs.

Conclusion

The maintenance of a cardboard packaging cutting tool should include:

-

Regular cleaning

-

Lubrication of moving parts

-

Knife maintenance

-

Electrical system inspection

-

Safety equipment testing

-

Frame structure inspection

-

Operator training

By implementing these measures, you can ensure that your CNC cardboard cutting machine continues to operate reliably, efficiently, and safely for years to come.

Call to Action

Looking for a reliable cardboard cutter or need professional advice on machine maintenance?

👉 Contact us today for a free consultation, sample cutting test, or the latest price list.