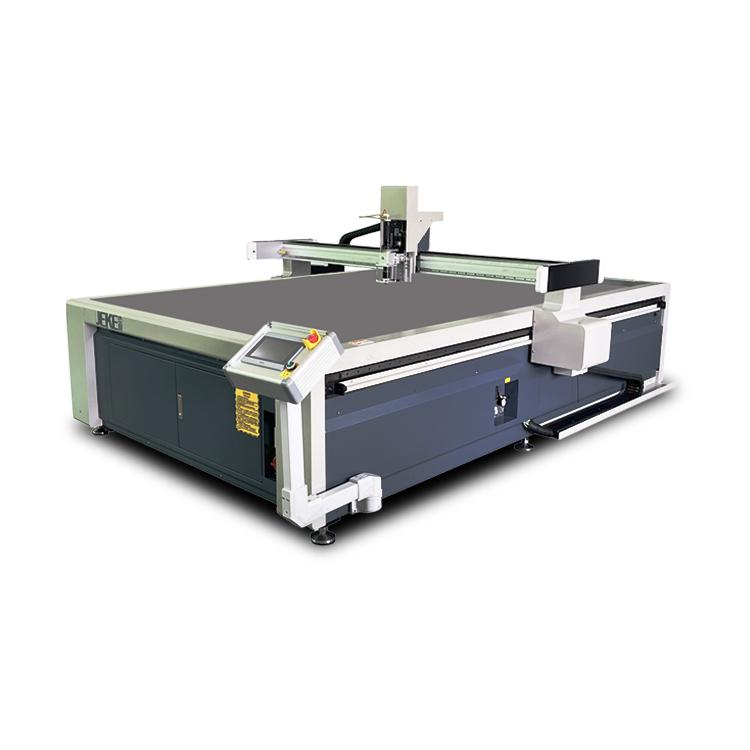

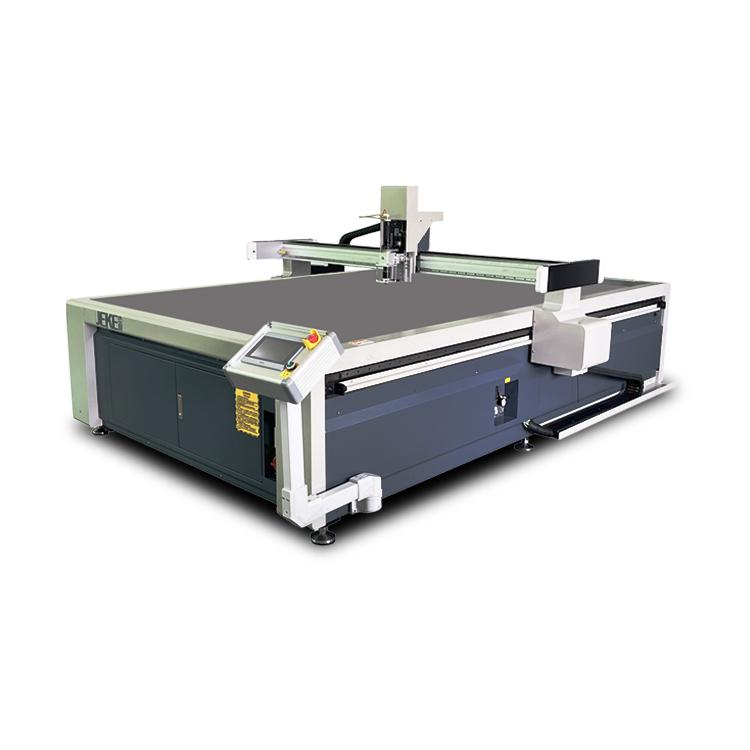

Digital leather cutting machine is an automatic industrial CNC cutting system suitable for leather, leather, carpets, floor mats, leather seats, leather shoes, leather jackets, leather pants, wallets, car seat cushions, metal wire ring pads, and car interiors. Digital precision leather cutting machines are widely used in industries such as clothing, shoes, furniture, sports goods, packaging, home textiles, decorations, and automobiles.

This digital fabric cutting machine is also known as a CNC knife cutting machine, industrial cutting machine, digital leather cutting system, digital leather cutting machine, precision leather cutting machine, digital leather cutting machine, digital textile cutting machine, industrial leather cutting machine, industrial textile cutting machine, etc.

Why choose a leather CNC cutting machine?

Precision, efficiency, and versatility make CNC leather cutting machines an excellent choice for leather and textile applications. The precise and reliable cutting produced by CNC cutting machines enables detailed patterns and reduces material waste. By ensuring precise coordination between all components, faults can be minimized to the greatest extent possible.

These devices improve productivity as they automate the cutting process. Because it saves time and personnel costs, it is particularly advantageous for large-scale manufacturing. The materials that CNC fabric cutting machines can handle include various types of fabrics, leather, and synthetic materials. Because of this, they can be used for various things, such as interior decoration and clothing industry, packaging industry, shoe-making industry, etc.

The clear and smooth edges produced by CNC cutting do not require additional polishing. No need to make knife molds, thanks to CNC technology, design drawings can be easily adjusted, making it easier to produce unique patterns or consistently repeat complex cuts.

CNC leather cutting machine parameters:

| Model |

JK-1625-1 |

| Working area |

1600×2500mm |

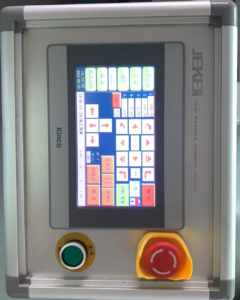

| Control system |

Kinco touch screen control system |

| Precision |

±0.01mm |

| Cutting thickness |

≤50mm |

| Maximum cutting speed |

500-1000mm/s |

| Safety device |

Infrared sensors |

| Drive system |

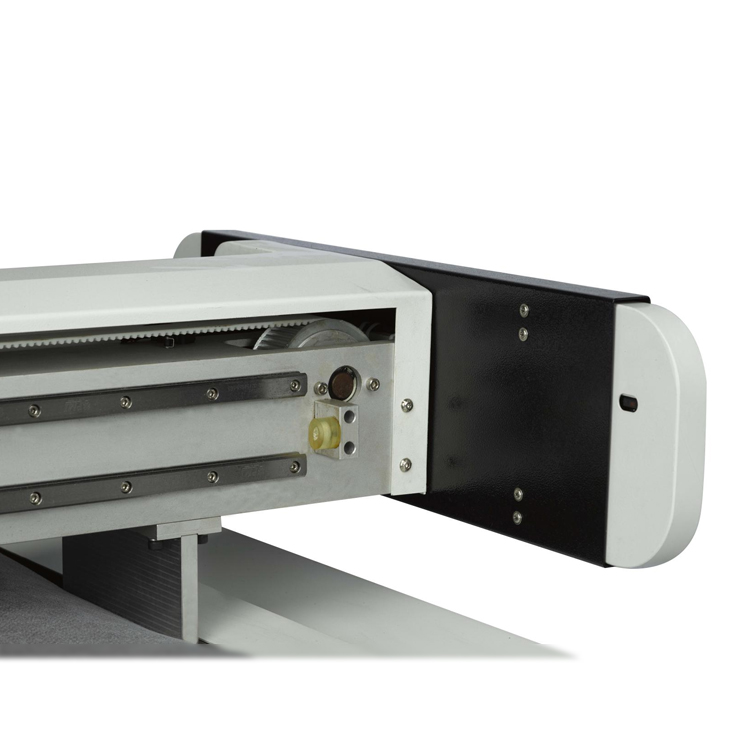

Inovance servo motor |

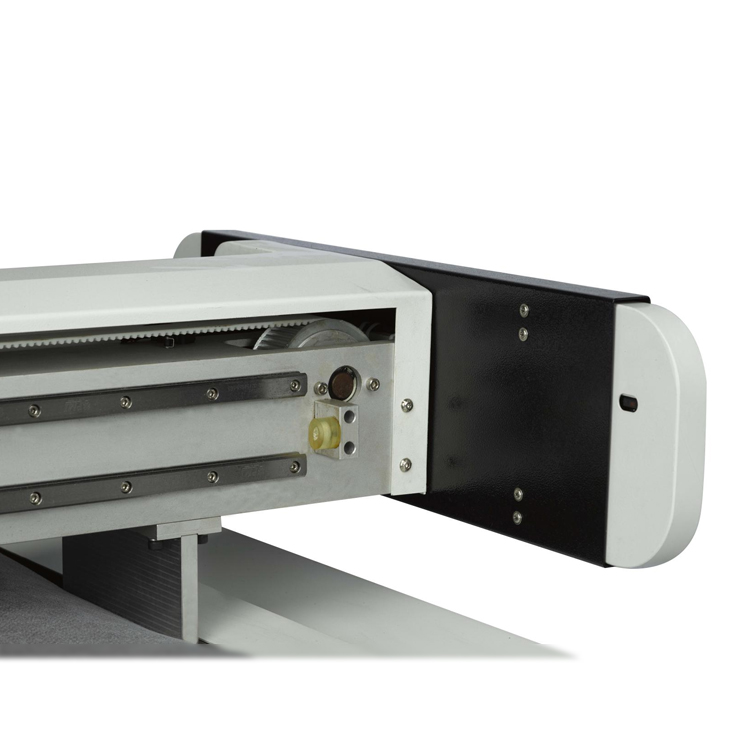

| Transmission system |

Taiwan square linear guide and belt |

| Graphic format supported |

DST,PLT, BMP, DXF, DWG, AI, LAS, etc. |

| Vacuum pump |

5KW high-power vacuum pump |

| Working table |

Flat table or Automatic feeding table |

| Voltage |

380V±10%, 50Hz or 220V±10%, 60Hz |

| Machine Size |

3570mmx2290mmx1165mm |

1. Increased Efficiency and Productivity

- Fast Cutting Speed: Automated cutting machines can process leather materials much faster than manual methods, improving throughput and enabling businesses to meet higher demand.

- 24/7 Operation: These machines can operate continuously with minimal supervision, allowing businesses to maximize output without breaks or downtime.

2. Precision and Accuracy

- High Precision: Digital cutting machines are equipped with advanced software and sensors to ensure precise cuts, minimizing material waste and ensuring consistent quality in every piece of leather.

- Complex Shapes and Designs: The automation allows for intricate, complex patterns and designs that would be difficult to achieve by hand, making it ideal for high-end leather products like fashion accessories, automotive interiors, and furniture.

3. Cost-Effective

- Reduced Labor Costs: Automation reduces the need for manual labor, lowering labor costs while improving efficiency and consistency.

- Minimal Material Waste: The software optimizes cutting paths to maximize the use of the leather, reducing waste and saving on raw material costs.

4. Versatility

- Customization: These machines can handle a wide variety of leather grades and thicknesses, making them versatile for different industries (fashion, upholstery, automotive, etc.).

- Multi-Functionality: Many digital leather cutting machines can perform other functions, such as engraving, embossing, or even stitching, expanding their application range.

5. Improved Safety

- Automated Process: With reduced human involvement, the risk of workplace injuries caused by sharp tools or equipment malfunctions is significantly minimized.

- Smart Features: Many advanced systems include safety features like automatic shutdowns or emergency stops, further reducing the risk of accidents.

6. Better Quality Control

- Consistent Output: Automation ensures that every cut is identical, improving the overall quality and consistency of finished products.

- Real-Time Monitoring: Many systems have integrated monitoring tools that track production progress, identify potential issues, and help with preventive maintenance, ensuring the equipment runs optimally.

7. Data-Driven Insights

- Production Data: Advanced machines collect data on production performance, cutting times, and material usage, which can be analyzed to optimize operations and reduce inefficiencies.

- Integration with Other Systems: These machines can be integrated with enterprise resource planning (ERP) and supply chain management systems for smoother, data-driven decision-making.

8. Space-Saving and Compact Design

- Compact Footprint: Many digital cutting machines are designed to be space-efficient, which is valuable for businesses with limited floor space.

9. Reduced Lead Times

- Quick Setup: Once the cutting files are prepared, the machine can start production immediately, significantly reducing lead times compared to traditional methods that involve more manual setup.

10. Environmental Benefits

- Less Material Waste: With precise cutting, less leather is wasted, leading to a more sustainable process.

- Energy Efficiency: Many modern systems are designed to use less power than older, less efficient machinery, reducing the overall energy consumption of the factory.

Overall, a fully automatic industrial digital leather cutting machine represents a smart investment for companies seeking to stay competitive in fast-paced markets where high-quality, cost-effective production is key.

Characteristics of Automatic Digital Leather Cutting Machine:

An Automatic Digital Leather Cutting Machine typically comes with a range of advanced features that enhance its performance, precision, and ease of use. Below are some key characteristics that define this type of machine:

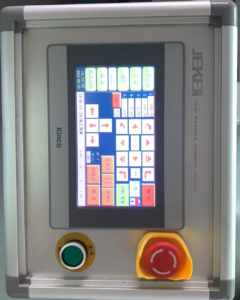

1. Advanced Digital Control System

- CNC Control: The machine is typically operated through a computer numerical control (CNC) system, allowing for precise cutting based on pre-programmed designs.

- Touchscreen Interface: A user-friendly touchscreen interface for easy programming, monitoring, and real-time adjustments.

- Software Integration: It integrates with design software (such as CAD or CAM software) to directly import and cut digital files.

2. High Cutting Precision

- Laser or Knife Cutting Technology: These machines often utilize either laser cutting or high-precision rotary knives to cut leather. Both options allow for intricate, detailed cuts with minimal deviation.

- Cutting Accuracy: High levels of accuracy (often in millimeters or even microns) ensure that complex patterns and designs are executed without errors.

3. Automatic Material Feeding and Handling

- Automatic Feeding System: The machine can automatically feed the leather into the cutting area, reducing manual labor and increasing throughput.

- Material Positioning: The material can be positioned automatically using suction or mechanical clamps to hold the leather in place during cutting.

4. Multi-Tool Capability

- Interchangeable Tools: Some machines come with interchangeable heads or tools, such as blades for cutting, lasers for engraving, or markers for drawing, making them versatile for different applications.

- Tool Adjustments: Automated adjustments for different materials or thicknesses can be made seamlessly, improving workflow and flexibility.

5. Optimized Cutting Path

- Cutting Path Optimization Software: The machine uses sophisticated algorithms to optimize cutting paths, reducing material waste and maximizing yield from each piece of leather.

- Minimized Waste: The software ensures that the cuts are placed in the most efficient manner, maximizing the use of the leather and reducing scrap.

6. High-Speed Operation

- Fast Cutting Speed: These machines are designed for high-speed operation, capable of cutting large volumes of leather without sacrificing precision.

- Continuous Operation: Some machines are designed for 24/7 operation, enabling large-scale production without interruption.

7. Multi-Material Capability

- Versatility: While primarily designed for leather, many digital cutting machines can also handle other materials such as fabric, rubber, synthetics, and plastics, expanding their application range.

- Thickness Adaptability: These machines are capable of cutting various thicknesses of leather, from soft garment leather to thicker upholstery materials.

8. Automatic Nesting and Design Optimization

- Nesting Software: The machine can automatically nest the patterns within the leather sheet to maximize material use and minimize waste.

- Design Flexibility: The system can handle intricate designs, patterns, and multiple layers, making it ideal for custom orders or complex projects.

9. Real-Time Monitoring and Diagnostics

- Production Monitoring: Integrated sensors and software allow operators to monitor the cutting process in real time, ensuring optimal performance.

- Error Detection: The system can automatically detect issues such as material misalignment, tool wear, or cutting errors and provide diagnostics to prevent production disruptions.

10. Automatic Material Ejection

- Automatic Ejection: After cutting, the machine automatically ejects the finished pieces or remnants, reducing manual handling and speeding up the production cycle.

- Sorting Functionality: Some advanced models can even sort the cut pieces based on size or type, streamlining the post-production process.

11. Energy Efficiency

- Low Power Consumption: Many modern cutting machines are designed to be energy-efficient, reducing operational costs while maintaining high performance.

- Sustainable Design: With minimal material waste and efficient use of energy, these machines can contribute to a more sustainable manufacturing process.

12. High-Quality Finished Products

- Clean Cuts: The cutting edges are smooth and clean, ensuring that the finished leather products have a professional, high-quality appearance.

- No Post-Processing Needed: Unlike manual cutting methods that may leave rough edges, digital cutting eliminates the need for additional finishing or trimming in most cases.

13. Customization and Automation

- Customizable Settings: Users can adjust cutting speed, pressure, and depth for different types of leather and design requirements.

- Automation Features: Many models offer automation in adjusting the parameters based on the specific leather type or cutting requirements, reducing the need for manual intervention and optimizing production time.

14. Space-Saving Design

- Compact and Modular: Some automatic leather cutting machines are designed to be compact, making them suitable for factories with limited space. They can also be modular, allowing for customization based on space and production needs.

15. Safety Features

- Safety Sensors: Automatic systems often include sensors to detect any irregularities or safety hazards, stopping the machine to prevent accidents.

- Enclosed Design: Some machines come with safety enclosures or covers to protect operators from the moving parts.

Application of JEKE Automatic Digital Knife Leather Cutting Machine:

The automatic digital knife leather cutting machine is applied in the industrial manufacturing of sofas, seats, car seat covers, car mats, car carpets, handbags, footwear, clothing, composite materials, luggage, automotive, advertising and printing, electronics, decoration, furniture, packaging, etc.

Industrial digital knife cutting machine cutting samples:

leather

carpet

Automotive Interior

Maintenance Tips for CNC Leather Cutting Machines (with Common FAQs)

Proper maintenance of your CNC leather cutting machine is essential for ensuring its longevity, efficiency, and accuracy in production. Here are six important maintenance tips for keeping your machine in optimal condition:

1. Regular Cleaning of the Machine

- Tip: Keep the machine clean and free of dust, debris, and leather scraps. Dust and dirt can affect the performance of the motors, sensors, and cutting tools.

- How: Use a soft cloth to wipe the surfaces and a vacuum or air compressor to remove any dust or small particles from the machine’s components.

2. Check and Lubricate Moving Parts

- Tip: Lubricate the moving parts, such as the rails, motors, and cutters, to ensure smooth operation and prevent wear and tear.

- How: Use appropriate lubricants as recommended by the manufacturer and apply them to the machine’s guide rails, ballscrews, and other moving components.

3. Monitor Cutting Tools for Wear and Tear

- Tip: Regularly inspect the cutting tools (blades, or rotary knives) for signs of wear. Worn-out tools can lead to poor cutting performance and damage the leather material.

- How: Replace worn-out tools promptly and ensure they are properly aligned for precise cuts.

4. Calibrate the Machine Regularly

- Tip: Ensure that the machine is calibrated correctly to maintain cutting accuracy and prevent misalignments.

- How: Perform periodic calibration checks using the machine’s built-in diagnostic tools or follow the manufacturer’s calibration procedure.

5. Check and Replace the Filters

- Tip: Regularly check and replace air or dust filters to maintain optimal airflow and prevent overheating or system failure.

- How: Replace filters as per the manufacturer’s recommendations, typically after every 300 to 500 hours of machine operation.

6. Update Software and Firmware

- Tip: Keep the CNC machine’s software and firmware up to date to benefit from new features, bug fixes, and performance improvements.

- How: Periodically check for software updates provided by the machine manufacturer and install them to keep the system running smoothly.

Common FAQs About CNC Leather Cutting Machines

1. How often should I clean my CNC leather cutting machine?

- Answer: You should clean your machine after every use to prevent dust and debris buildup. For deep cleaning, do it at least once a week, depending on the frequency of machine use.

2. How can I prevent wear and tear on the cutting tools?

- Answer: Regularly inspect and maintain the cutting tools. Properly calibrate the machine, and replace tools as soon as they show signs of wear to ensure smooth and accurate cuts.

3. What should I do if the machine is cutting inaccurately?

- Answer: If the machine is cutting inaccurately, check the calibration, the condition of the cutting tools, and whether there is any misalignment in the system. Recalibrate the machine and replace worn tools to resolve the issue.

4. How often do I need to lubricate the moving parts?

- Answer: Lubricate the machine’s moving parts every 100-200 hours of operation, or as specified in the manufacturer’s manual. Regular lubrication ensures smooth motion and prevents excessive wear.

5. Can I continue to use the machine without replacing the filters?

- Answer: It’s not recommended to run the machine without replacing the filters as dirty filters can reduce airflow, causing overheating and potentially damaging the machine. Replace filters regularly to maintain performance.

6. Why does the CNC machine stop working during production?

- Answer: The machine may stop due to a variety of issues, including tool wear, overheating, misalignment, or software malfunctions. Always check the error messages and perform basic troubleshooting, such as checking tool status, machine calibration, and system updates.

Why Regular Maintenance is Crucial for CNC Leather Cutting Machines

Regular maintenance ensures that your CNC leather cutting machine performs optimally, extends its service life, and helps you avoid costly repairs or downtime. By adhering to proper maintenance practices, you can ensure high-quality cuts, improve production efficiency, and keep your operations running smoothly.