We believe we can assist you in solving challenges related to CNC machinery.

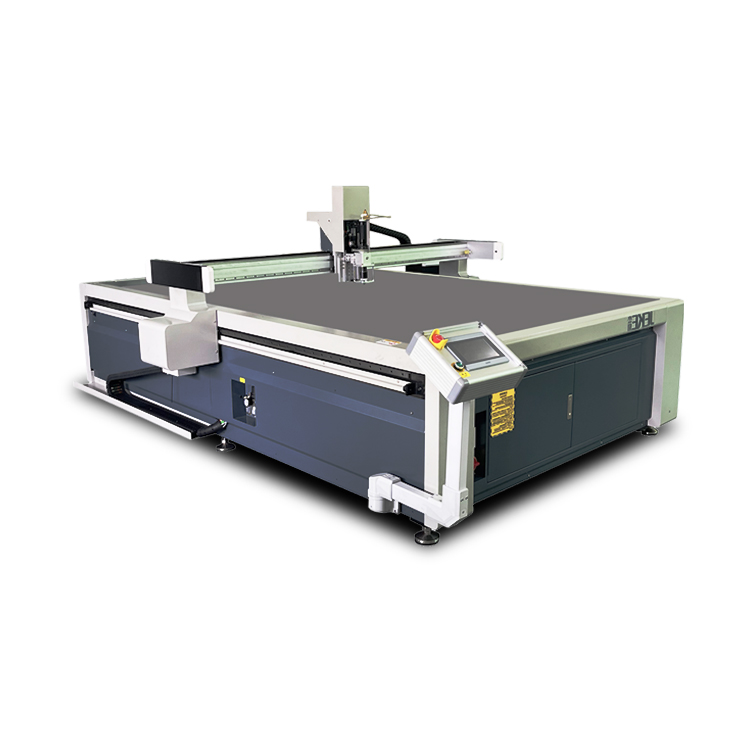

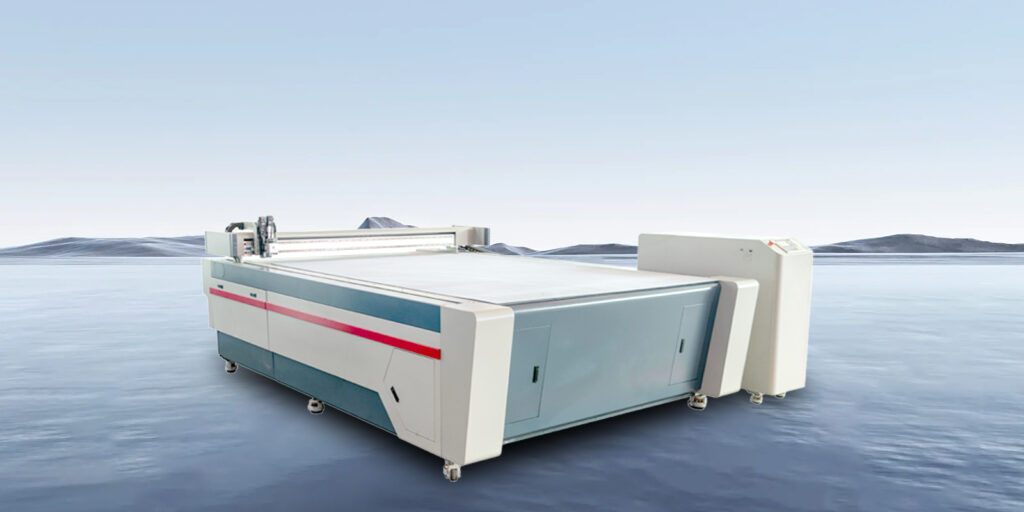

In the rapidly evolving world of manufacturing and fabrication, CNC (Computer Numerical Control) cutting machines have become essential tools for achieving precision and efficiency. Among the leading brands in this domain is JEKE, known for its innovative solutions and advanced technology. This article explores the types of CNC cutting equipment, the advantages of specific machines, and how to select the right equipment for your needs.

Your brand, your design. That’s why we offer complete flexibility with the CNC you need. Whether it’s adjusting the size, style, color, or features, let us know, and we’ll do our best to deliver exactly what you envision.

This insightful exploration delves into the latest developments in CNC cutting technology, artificial intelligence, and automation.

alice_liu@jekecnc.com

+86 19065116408

Copyright © 2024 jekecnc.com. All rights reserved.

We will arrange for a specialist to contact you immediately.