Laser cutting is one of the most advanced manufacturing technologies in today’s industrial world. Although it may take some effort to learn, many find it exciting and even fun to use once they get started. For beginners, however, it is essential to understand the fundamentals of laser cutting machines before fully exploring their potential.

This beginner-friendly guide by JEKE CNC will walk you through everything you need to know about laser cutting:

-

What laser cutting is and how it works

-

The benefits and advantages of laser cutting machines

-

Frequently asked questions (FAQ)

-

Tips on how to choose the right laser cutting machine for your business

What Is Laser Cutting?

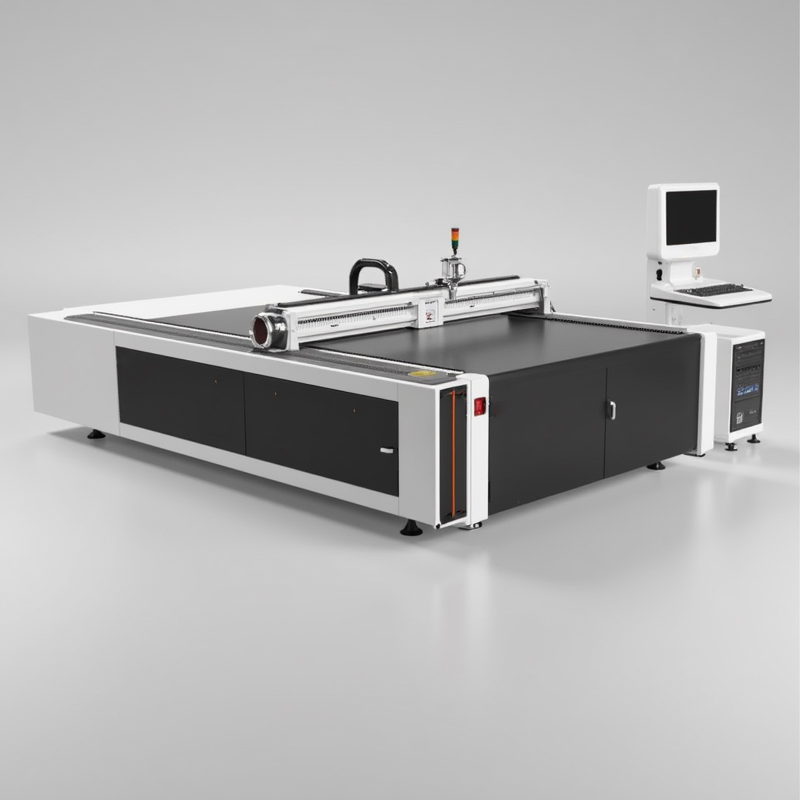

A laser cutting machine is a computer-aided manufacturing tool that directs a focused laser beam along a programmed path to cut, engrave, or mark materials. Unlike additive manufacturing methods (such as 3D printing), laser cutting is a subtractive manufacturing process—it removes material to create precise cuts, holes, or engravings.

Laser cutting technology is widely used in industries such as:

-

Metal fabrication (stainless steel, carbon steel, aluminum, copper)

-

Electronics (circuit boards, components)

-

Automotive and aerospace (sheet metal, structural parts)

-

Advertising & signage (acrylic, MDF, PVC, lettering)

-

Art, craft, and design (wood engraving, leather cutting, decorative patterns)

Advantages of Laser Cutting Machines

Why are laser cutting machines so popular across industries? Here are the key benefits:

-

High Precision – Laser cutters achieve tolerance levels of ±0.02 mm, delivering clean and detailed cuts.

-

Versatility – Capable of cutting metals, plastics, wood, fabrics, leather, and more.

-

Speed and Efficiency – Faster than traditional cutting methods, especially for complex patterns.

-

Automation – Controlled by CNC software, reducing human error and improving consistency.

-

Low Waste – Optimized nesting software maximizes material usage, minimizing scrap.

-

Non-contact Process – No mechanical force applied, reducing wear and material deformation.

Types of Laser Cutting Machines

Laser cutting machines can be classified by their laser source:

-

Fiber Laser Cutting Machine

-

Best for metals such as stainless steel, carbon steel, aluminum, brass, and copper.

-

High efficiency, lower maintenance costs, and long service life.

-

-

CO₂ Laser Cutting Machine

-

Ideal for non-metallic materials such as acrylic, wood, leather, and fabric.

-

Widely used in advertising, decoration, and handicrafts.

-

-

Hybrid or Custom Systems

-

Designed to handle both metals and non-metals for diverse applications.

-

Frequently Asked Questions (FAQ)

Q1: What materials can a laser cutter cut?

A: Metals (steel, aluminum, copper), plastics (acrylic, PVC), wood, leather, textiles, and more.

Q2: Is laser cutting safe?

A: Yes, with proper safety features (protective covers, fume extraction, sensors). JEKE CNC machines are built with international safety standards.

Q3: How do I choose the right laser cutting machine?

A: Consider the material type, thickness, production volume, and your budget. Fiber lasers are best for metals, while CO₂ lasers excel in non-metals.

Q4: What industries use laser cutting most?

A: Packaging, metal fabrication, automotive, aerospace, advertising, furniture, and custom design industries.

How to Choose the Right Laser Cutting Machine

When investing in a laser cutting machine, keep these factors in mind:

-

Material requirements (metal vs non-metal)

-

Cutting thickness and power (1kW to 12kW fiber lasers for metals)

-

Worktable size (small format for crafts vs large format for industrial sheets)

-

Budget and ROI (entry-level vs high-production systems)

-

After-sales support (training, installation, spare parts availability)

At JEKE CNC, we offer a wide range of fiber laser cutters and CO₂ laser machines, designed to meet both small business and large-scale manufacturing needs.

Laser cutting is a powerful, precise, and versatile technology that has transformed modern manufacturing. From high-speed industrial production to creative design applications, a laser cutting machine can significantly improve efficiency and product quality.

Whether you are a beginner looking to explore this technology or a manufacturer seeking a high-end solution, JEKE CNC provides reliable, cost-effective, and globally supported laser cutting machines tailored to your needs.

Ready to invest in a laser cutting machine that will upgrade your production?

👉 Contact JEKE CNC today for a free consultation, sample cutting test, or the latest quotation.

📧 Email: alice_liu@jekecnc.com

📞 Phone/WhatsApp: +86-19065116408

🌐 Website: www.jekecnc.com