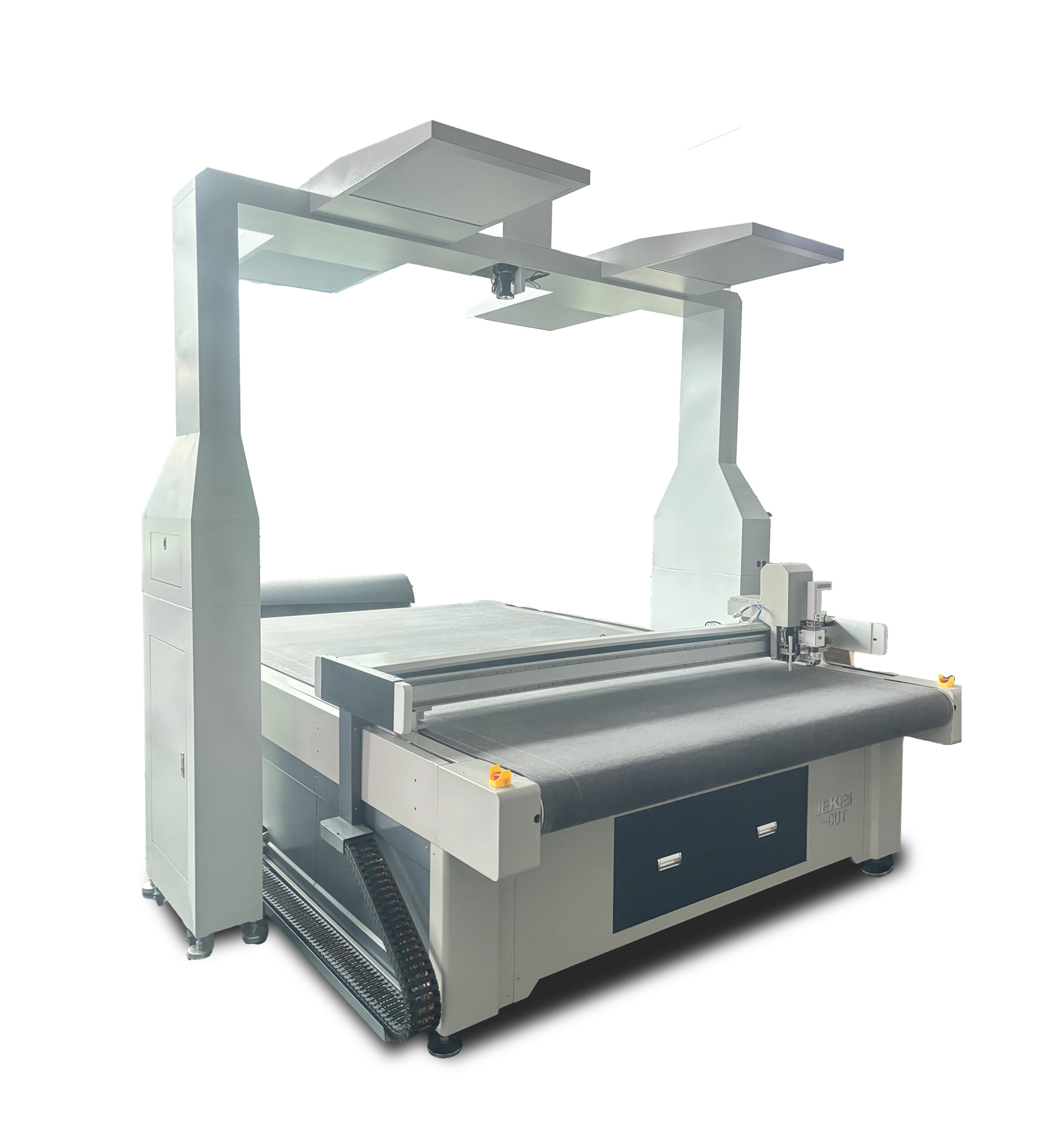

In today’s rapidly evolving manufacturing industry, CNC digital cutting machines have become essential equipment for improving production efficiency and precision. As the demand for intelligent production continues to rise, manufacturers need to rely on efficient and accurate machines to perform complex cutting tasks. CNC digital cutting machines, as core tools in industrial sectors, are widely used in various industries such as cardboard manufacturing, garment processing, and signage production.

Product Needs Analysis:

Manufacturers’ core needs are usually focused on improving production speed, reducing material waste, and enhancing product quality. CNC digital cutting machines can meet these needs through their high precision, automation, and flexibility. They can cut a variety of materials (such as cardboard, leather, fabrics, etc.) with accuracy, while supporting multiple file formats, making it easier to import and process design files.

Efficiency: CNC digital cutting machines use advanced computer numerical control systems to complete complex cutting tasks in a short amount of time, significantly increasing production efficiency.

Precision: With laser or vibrating knife technology, CNC machines can cut with micron-level accuracy, greatly improving product consistency and precision.

Cost Savings: Compared to traditional manual cutting methods, CNC cutting machines greatly reduce material waste, lowering production costs.

Market Competitiveness:

In today’s highly competitive market, CNC digital cutting machines provide manufacturers with a significant competitive edge in improving manufacturing efficiency and optimizing production processes. Firstly, the high level of automation reduces human errors, stabilizing the production process. Secondly, the versatility of the equipment makes it suitable for a wide range of manufacturing needs, offering strong market adaptability. Additionally, CNC digital cutting machines can seamlessly integrate with other automation production equipment, forming intelligent production lines that further enhance production capacity.

Enhanced Production Efficiency: Automation saves a substantial amount of labor costs and allows for quick adaptation to changes in production tasks.

Optimized Process Workflow: The precise cutting effects reduce the need for further processing, simplifying the workflow and shortening production cycles.

Procurement & Cooperation:

If you, as a manufacturer, are looking for equipment to boost productivity, the CNC digital cutting machine is undoubtedly your ideal choice. We offer a variety of models and configurations that cater to different industry needs. You can obtain our products through the following ways:

Online Consultation: Visit our website to learn more about our products and contact our sales team for detailed information.

Customized Solutions: Based on your specific needs, we can provide tailored cutting machine solutions to meet your production requirements.

Pricing & Procurement: We offer transparent pricing and flexible payment options to ensure a smooth purchasing process.

Industry Trends & Hot Topics:

In recent years, digital manufacturing and automation have become major trends in the global manufacturing industry. With the gradual adoption of smart factories, CNC digital cutting machines, as core equipment, are driving manufacturing toward more refined and intelligent directions. In the future, CNC digital cutting machines will not only be limited to traditional cutting applications but will also play a role in innovative fields such as 3D printing and personalized customization. As technology continues to evolve, the performance and functionality of CNC digital cutting machines are continually improving, providing manufacturers with a stronger competitive advantage.

Conclusion:

CNC digital cutting machines are undoubtedly an indispensable tool in modern manufacturing. They help enhance production efficiency, optimize manufacturing processes, and reduce production costs. If you’re interested in our products, feel free to visit our website for more information or contact us directly for quotes and technical support. Let us help you provide more efficient and intelligent solutions for your production.