When it comes to automotive upholstery, precision, speed, and efficiency are non-negotiable. As the automotive industry advances, so does the demand for high-quality leather interiors. Meeting these expectations calls for innovative technology, and CNC cutting machines have emerged as the game-changer. This article delves into how CNC cutting machines enable fast and effective automotive leather cutting and addresses common questions about this cutting-edge solution.

Why Choose a CNC Cutting Machine for Automotive Leather?

Speed and Precision in Every Cut

CNC cutting machines are powered by advanced software and precision tools that ensure each cut is accurate down to the millimeter. This is critical for automotive leather, where consistency affects the aesthetic and functional quality of car interiors.

Minimizing Waste

Automotive leather is a premium material, and every inch counts. CNC machines optimize material usage through intelligent nesting algorithms, significantly reducing waste. This not only saves money but also aligns with sustainable manufacturing practices.

Scalability for Diverse Needs

Whether you need small batch production or high-volume cutting, CNC machines adapt effortlessly. Their programmability allows manufacturers to switch between patterns and designs without manual intervention, saving time and effort.

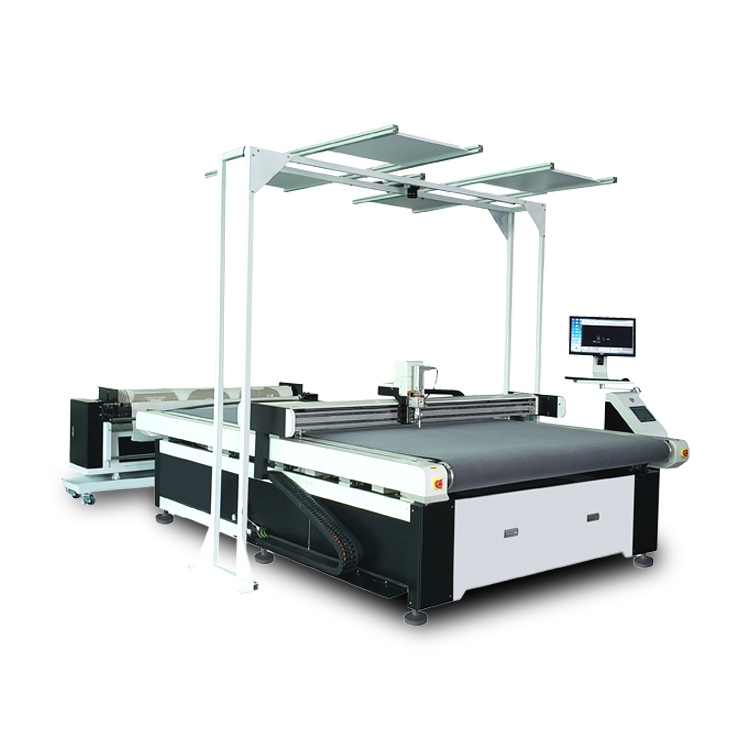

Key Features of CNC Cutting Machines for Automotive Leather

- Advanced Cutting Technology

CNC machines use high-frequency oscillating knives, laser technology, or other precision tools to handle even the toughest leather types. - Customizable Cutting Parameters

With adjustable settings for speed, pressure, and depth, these machines accommodate a variety of leather thicknesses and textures. - Software Integration

Integrated CAD/CAM software simplifies design creation and ensures seamless execution. Patterns can be uploaded digitally, minimizing errors. - User-Friendly Interface

Modern CNC machines are designed with intuitive interfaces, making them accessible for operators of varying skill levels.

How CNC Machines Enhance Productivity

Automated Workflows

Automation is the hallmark of CNC technology. From material loading to precise cutting, automation reduces manual labor and operational errors.

Faster Turnaround Times

Traditional cutting methods often involve time-consuming manual adjustments. CNC machines streamline the process, completing jobs faster without compromising quality.

Improved Worker Safety

By eliminating the need for handheld tools, CNC machines reduce the risk of workplace injuries, creating a safer environment for operators.

Common Applications in the Automotive Industry

CNC cutting machines cater to various leather applications, including:

- Car Seats: Ensuring flawless upholstery with intricate stitching patterns.

- Dashboard Covers: Delivering precision for complex shapes and designs.

- Steering Wheel Covers: Cutting small, detailed pieces accurately.

- Door Panels: Producing consistent and aesthetically pleasing finishes.

FAQs about CNC Cutting Machines for Automotive Leather

1. What types of leather can CNC machines cut?

CNC machines handle various types of leather, including natural, synthetic, and eco-friendly leather. The adjustable settings make them suitable for materials of different thicknesses.

2. How does a CNC machine improve leather utilization?

CNC machines utilize advanced nesting software to maximize material use. This reduces leather wastage, saving costs and supporting sustainable production.

3. Are CNC machines difficult to operate?

Modern CNC machines are equipped with user-friendly interfaces and training resources, making them accessible even for beginners.

4. What maintenance is required for a CNC cutting machine?

Regular maintenance includes cleaning the cutting tools, updating software, and ensuring components are in good working condition. Manufacturers typically provide comprehensive maintenance guides.

5. How fast can a CNC machine cut automotive leather?

Cutting speeds vary by model and material but can reach up to 1,500 mm/s, ensuring high productivity without sacrificing precision.

6. Is it possible to cut complex designs with a CNC machine?

Absolutely. CNC machines excel in intricate and detailed patterns, making them ideal for customized automotive designs.

Why Invest in a CNC Cutting Machine?

Investing in a CNC cutting machine is a strategic move for any automotive leather manufacturer. It offers:

- Enhanced Precision: Consistent quality across all production batches.

- Cost Savings: Reduced waste and labor costs.

- Sustainability: Efficient material utilization.

- Future-Ready Technology: Compatibility with evolving design and production trends.

Conclusion

CNC cutting machines are revolutionizing the way automotive leather is processed, offering unparalleled efficiency, precision, and versatility. By adopting this technology, manufacturers can meet the rising demand for high-quality car interiors while staying competitive in the market.

If you’re ready to elevate your leather-cutting capabilities, consider exploring CNC solutions tailored to the automotive industry. The future of efficient and sustainable production starts here.