Introduction

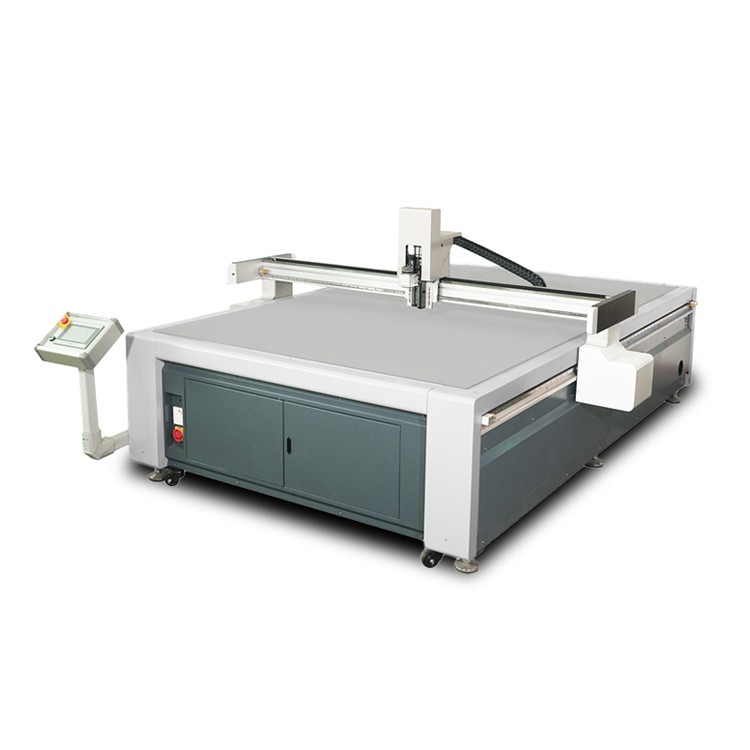

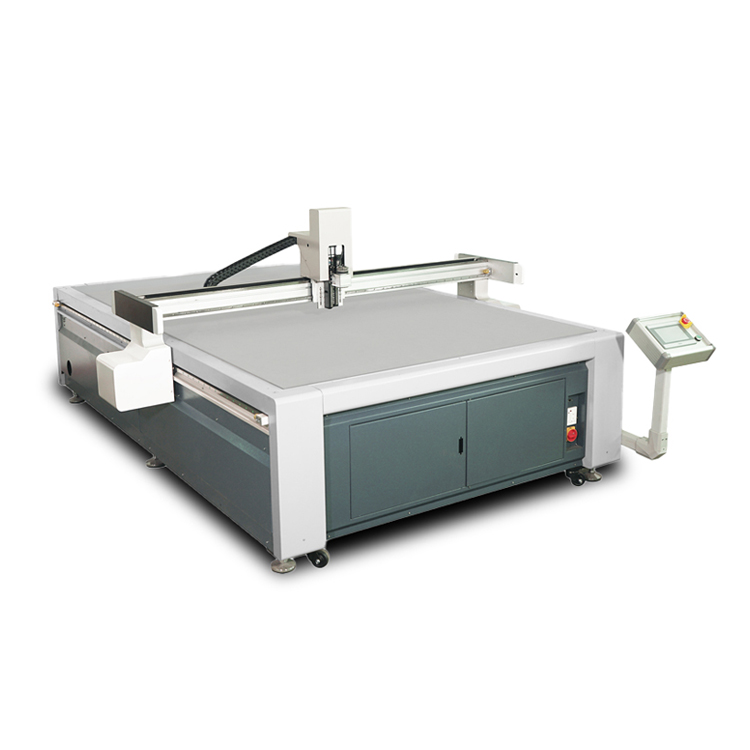

In today’s rapidly advancing industrial landscape, CNC (Computer Numerical Control) cutting machines have become essential for businesses aiming to improve efficiency, precision, and production speed. JEKE’s range of CNC cutting machines offers solutions tailored for both small businesses and large factories, allowing each to produce high-quality products with minimal manual labor. This guide helps you understand how to select the right CNC cutting machine by determining your budget, understanding material and size requirements, defining processing and precision needs, and exploring the various machine options suited for your business.

1. Determine Your Budget

Before investing in a CNC cutting machine, it’s crucial to define your budget. CNC machines come in various types and capabilities, ranging from entry-level models suitable for small businesses to advanced, high-capacity machines designed for factories. Setting a budget helps narrow down choices and ensures that you select a machine that balances cost with performance. Consider not only the initial purchase price but also additional costs, such as maintenance, software, tooling, and training. Choosing a CNC machine within your budget allows you to get the best ROI for your specific business requirements.

2. Determine the Materials and Dimensions You Need to Cut and Process

Knowing the type of materials and sizes that your CNC cutting machine will handle is essential for selecting the right model. Common materials for CNC cutting include metals (like aluminum and steel), wood, plastic, fabric, and leather. JEKE offers CNC cutting machines with a wide variety of cutting capabilities to accommodate these different materials.

Additionally, consider the thickness and dimensions of the materials. Small businesses that primarily handle thin materials can opt for a CNC router or laser cutting machine, while factories needing to cut thicker or harder materials might need a plasma or waterjet cutter. JEKE’s CNC cutting machines are equipped to handle a range of material sizes, ensuring versatility across different projects.

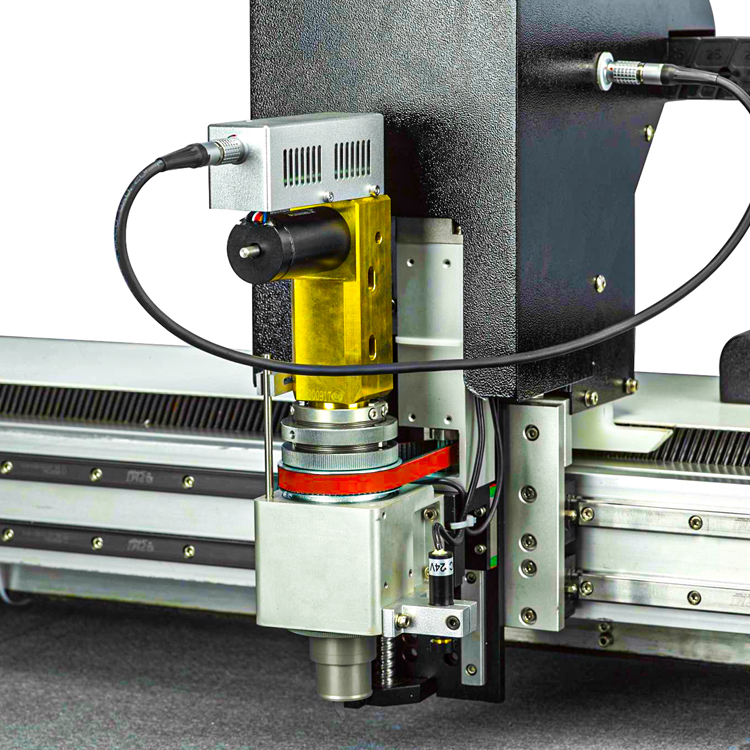

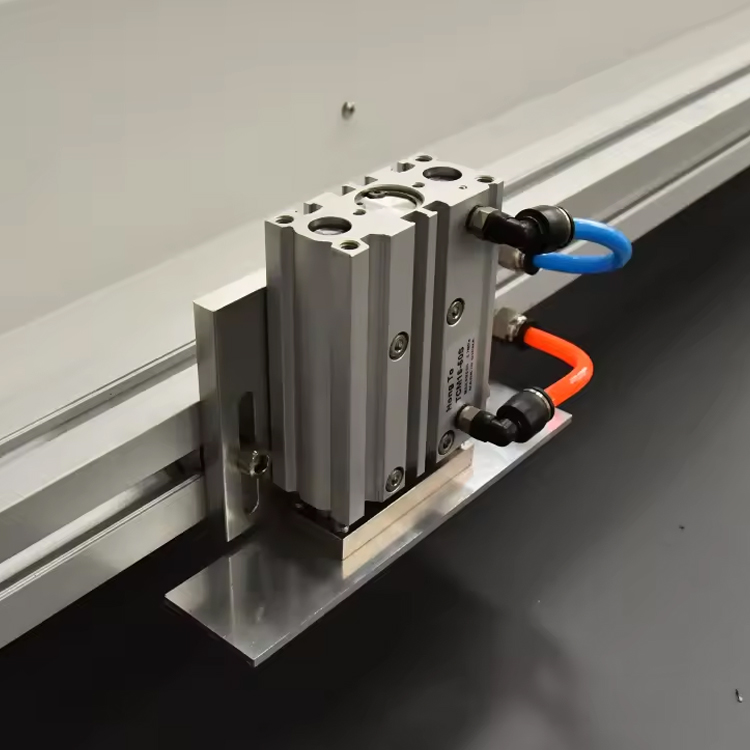

3. Determine Your Processing Requirements and Precision Needs

Every business has unique processing and precision requirements. For example, CNC milling machines are ideal for intricate designs and high-precision needs, while CNC routers are more suited for simple cuts and larger material surfaces. Precision is critical in industries such as aerospace and medical manufacturing, where even the smallest error can be costly. JEKE’s CNC machines are designed to deliver precise cuts with minimal error, ensuring consistent quality.

Understanding your production scale and accuracy requirements will help you choose a machine that aligns with your output goals. For example, if your business requires high-speed, repetitive cuts, consider a machine with automation capabilities, such as robotic arms for loading and unloading. Factories may benefit from larger, industrial-grade CNC machines capable of running multiple shifts without compromising accuracy.

4. Which CNC Machine Should I Purchase for My Small Business?

The decision on which CNC machine to purchase depends largely on your business’s production needs. Below are some popular types of CNC machines suitable for small businesses:

- CNC Routers: Perfect for woodworking, plastics, and light metalworking, CNC routers are versatile, cost-effective, and easy to use. They are suitable for small businesses involved in furniture, signage, and cabinetry.

- CNC Milling Machines: These machines are ideal for creating complex, precise shapes and are often used in industries requiring fine detail, such as jewelry and electronics.

- Laser Cutters: Known for their accuracy and speed, laser cutters are suitable for materials like wood, acrylic, and certain metals. They are widely used in the fashion, electronics, and arts industries.

- Plasma Cutters: Suitable for cutting conductive metals, plasma cutters are ideal for businesses in metal fabrication. They can handle thicker materials than laser cutters, making them a popular choice for automotive and manufacturing industries.

- Waterjet Cutters: For businesses that need to cut thick, hard materials like stone or ceramics, waterjet cutters provide a non-thermal cutting method, preserving the material’s integrity and precision.

Each of these machines offers unique features, and the choice depends on the specific needs and budget of your business. JEKE’s CNC cutting machine lineup includes options across these categories, ensuring there’s a machine suited for every business type and size.

5. How Are CNC Machine Tools Used in Business?

CNC machines play a significant role in modern manufacturing, allowing businesses to create products with high precision and repeatability. Here are some common ways CNC machines are used in business:

- Prototyping and Design: CNC machines enable rapid prototyping, allowing designers to test and modify ideas quickly and efficiently. This is especially beneficial for industries like automotive and aerospace, where precision is paramount.

- Production of Customized Products: CNC machines allow for customization without extensive retooling. This capability is particularly valuable in industries like jewelry, signage, and custom furniture.

- Large-Scale Production: For factories, CNC machines support high-volume production. With automation, businesses can operate continuously, maximizing output while minimizing downtime.

- High-Precision Manufacturing: CNC machines are widely used in sectors requiring precision, such as medical equipment manufacturing, where even the smallest discrepancies can affect product safety and performance.

Frequently Asked Questions (FAQs)

1. What is a CNC cutting machine?

A CNC cutting machine uses computer-controlled movements to cut, shape, and engrave materials with precision. These machines are highly versatile and can work with materials like metal, wood, plastic, and fabric.

2. How does a CNC machine differ from traditional machining?

Unlike traditional machining, which requires manual operation, CNC machines operate automatically based on a programmed sequence. This results in higher accuracy, speed, and repeatability.

3. What materials can JEKE CNC machines cut?

JEKE CNC machines are capable of cutting a variety of materials, including metals, plastics, wood, and composites. Certain models are also suitable for cutting stone, leather, and textiles, depending on the type and model.

4. How do I determine which CNC machine is right for my business?

Consider your budget, material types, and production needs. Small businesses may benefit from CNC routers or laser cutters, while factories may require more robust machines like waterjet or plasma cutters.

5. How much maintenance is required for a CNC machine?

CNC machines require regular maintenance, such as cleaning, lubrication, and software updates. Routine checks help prevent breakdowns and ensure optimal performance.

6. What is the lifespan of a CNC machine?

With proper care and maintenance, a CNC machine can last anywhere from 10 to 15 years or longer. JEKE CNC machines are built for durability and come with warranties to support their long-term performance.

7. Are JEKE CNC machines compatible with different software?

Yes, JEKE CNC machines are compatible with a variety of CAD/CAM software options, making them adaptable to different design and programming requirements.

8. Can CNC machines operate without an operator?

While CNC machines can run automated programs, human oversight is still essential to monitor quality and ensure safety, especially in high-volume production environments.

9. How precise are JEKE CNC cutting machines?

JEKE CNC machines offer precision up to 0.001 inches, ensuring accuracy across all production stages, which is ideal for industries where precision is critical.

10. Are CNC machines cost-effective for small businesses?

Yes, CNC machines can be a cost-effective investment for small businesses. They reduce labor costs, improve production speed, and allow for greater product customization, providing a strong return on investment.

Conclusion

Selecting the right CNC cutting machine can transform your business operations, enhancing both productivity and product quality. By assessing your budget, understanding your material requirements, and determining the necessary precision, you can find the perfect CNC machine for your business needs. JEKE’s range of CNC machines offers diverse solutions, from compact models for small businesses to heavy-duty machines for factories, all designed to provide reliable performance and precision. Start exploring your options with JEKE today and discover how the right CNC cutting machine can drive your business toward greater success.