In today’s competitive manufacturing landscape, efficiency is key to staying profitable and competitive. CNC (Computer Numerical Control) cutting machines have emerged as powerful tools for manufacturers looking to reduce operational costs, increase productivity, and achieve higher profit margins. By automating and streamlining the cutting process, CNC cutting machines help minimize waste, lower labor costs, and ensure precise, repeatable results. This article explores how CNC cutting machines contribute to cost reduction, address common concerns manufacturers may have, and answer frequently asked questions (FAQ) about CNC technology.

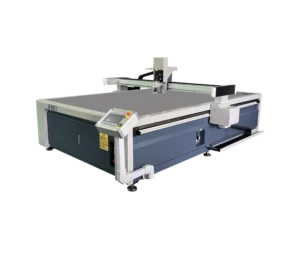

What is a CNC Cutting Machine?

A CNC cutting machine is an automated tool that uses programmed commands to precisely cut various materials, including metal, plastic, wood, and composites. Using software-driven instructions, these machines make cuts that are highly accurate and consistent, which reduces material waste and improves productivity. CNC cutting technology includes various methods, such as laser cutting, plasma cutting, water jet cutting, and router cutting, each of which is designed to suit different applications and materials.

Benefits of CNC Cutting Machines for Cost Reduction

- Reduced Material Waste

- Traditional manual cutting processes can lead to a significant amount of material waste due to errors and inconsistencies. CNC cutting machines, on the other hand, are programmed to follow precise paths, which ensures that each cut is as accurate as possible, minimizing the need for additional trimming or reworking. This level of accuracy means less material is wasted, reducing raw material costs.

- Lower Labor Costs

- CNC cutting machines are automated, meaning they require less manual labor to operate compared to traditional methods. Once programmed, they can work independently, allowing manufacturers to reduce the number of employees needed for the cutting process. This not only reduces labor costs but also allows staff to focus on other tasks, enhancing productivity across the board.

- Increased Production Speed

- With a CNC machine, cutting times are significantly reduced due to the high speed and efficiency of the equipment. Unlike manual cutting, which can be slow and labor-intensive, CNC machines are capable of operating around the clock with minimal supervision, leading to faster project turnarounds and increased throughput. The ability to produce parts quicker allows businesses to fulfill more orders, contributing directly to higher profit margins.

- Improved Consistency and Quality

- Consistency is critical in manufacturing, especially for high-volume orders. CNC cutting machines eliminate human error and ensure that every cut is identical, leading to better quality products. High-quality and consistent output not only satisfies customer demands but also reduces the risk of returns or rework, which can save time and money.

- Versatile Cutting Capabilities

- CNC cutting machines can handle a wide range of materials and intricate designs, which allows manufacturers to diversify their offerings without investing in multiple types of machinery. By using a single CNC machine for various cutting tasks, companies can save on equipment costs and reduce the space required in the production area.

- Energy Efficiency

- Compared to traditional cutting methods, CNC cutting machines often consume less energy due to their efficient motors and precision cutting. Lower energy consumption not only helps businesses save on utility bills but also reduces their environmental impact, which is increasingly important to customers.

How CNC Cutting Machines Boost Profit Margins

By reducing costs across multiple areas — from labor and material waste to energy consumption — CNC cutting machines enable businesses to retain more of their revenue as profit. Faster production and high-quality output also increase customer satisfaction and repeat orders, further boosting profitability. Additionally, the versatility of CNC cutting machines allows companies to expand into new markets without incurring significant additional costs, creating more revenue opportunities.

Frequently Asked Questions (FAQs) About CNC Cutting Machines

1. What types of materials can a CNC cutting machine handle?

CNC cutting machines are designed to work with a wide variety of materials, including metals (like steel, aluminum, and brass), plastics, wood, glass, foam, and composite materials. The type of cutting method used (e.g., laser, plasma, water jet) will depend on the material’s properties and thickness.

2. Are CNC cutting machines difficult to operate?

While CNC cutting machines require programming, most modern systems are designed to be user-friendly, with interfaces that are intuitive for operators. Many CNC machines come with software that simplifies the programming process, and manufacturers often provide training to ensure operators can use the equipment effectively.

3. How much can a CNC cutting machine reduce labor costs?

The exact reduction in labor costs depends on the specifics of the operation, such as the complexity and volume of work. However, CNC machines typically require only one operator to oversee multiple machines, which can lead to a significant reduction in labor hours and related expenses.

4. How do CNC cutting machines improve product quality?

CNC cutting machines follow programmed paths with high precision, meaning each cut is identical and repeatable. This consistency eliminates variances between parts and reduces the need for post-processing, resulting in high-quality, precise products that meet customer specifications.

5. What maintenance is required for CNC cutting machines?

Regular maintenance is essential to ensure the longevity and efficiency of CNC cutting machines. Basic maintenance tasks include cleaning the machine, inspecting and lubricating moving parts, and replacing any worn-out components. Most manufacturers provide maintenance schedules, and some offer maintenance services to support optimal machine performance.

6. How long does it take to see a return on investment (ROI) with a CNC cutting machine?

ROI on a CNC cutting machine varies based on factors like initial cost, usage frequency, and operational savings. For businesses with high production volumes, the ROI can be seen within a few months to a couple of years due to the significant reductions in labor and material costs.

7. Can a CNC cutting machine help with custom or complex designs?

Absolutely. CNC machines are highly programmable, enabling them to create intricate designs and shapes that would be challenging or impossible to achieve manually. This flexibility is particularly beneficial for businesses specializing in custom orders or prototyping.

8. How can CNC cutting machines help improve workflow efficiency?

CNC cutting machines streamline the workflow by automating the cutting process, reducing manual intervention, and allowing for a continuous production process. This efficiency not only speeds up production but also reduces the risk of errors, which further optimizes the entire manufacturing workflow.

Conclusion

CNC cutting machines offer manufacturers an effective way to lower costs, improve efficiency, and boost profit margins. With reduced labor requirements, minimized material waste, and consistent quality output, CNC machines contribute to a more streamlined and cost-effective production process. Additionally, their ability to handle diverse materials and intricate designs enables companies to expand their product offerings and cater to a broader market.

Investing in CNC technology is more than just acquiring a new piece of equipment; it’s about building a foundation for sustainable growth, higher profitability, and a competitive edge in a demanding market. As companies continue to adapt to changing industry demands, CNC cutting machines remain a reliable solution to meet efficiency and profitability goals.