In 2025, the vibrating knife cutting machine continues to evolve as one of the most advanced solutions for cutting flexible and semi-rigid materials. Unlike laser or traditional cutting methods, vibrating knife technology relies on high-frequency blade oscillation combined with 360° rotary cutting control, enabling clean, precise, and eco-friendly results.

With thousands of vibrations per minute, these machines are capable of performing vertical cuts, sharp corner cuts, and intricate patterns on materials such as paper, leather, textiles, foam, rubber, and composite boards. Due to their dust-free, odor-free, and smoke-free operation, vibrating knife cutters have become a preferred technology across multiple industries.

As we move into 2025, the technology has undergone several disruptive upgrades. Here are the top 5 innovations shaping the future of vibrating knife cutting machines.

1. AI-Powered Smart Cutting Systems

The latest vibrating knife machines are now integrated with AI-driven cutting software that can:

-

Automatically detect material type and thickness.

-

Optimize tool paths in real-time.

-

Minimize waste by intelligent nesting and layout planning.

This ensures higher accuracy, faster turnaround, and lower material costs.

2. Advanced Multi-Tool Integration

2025 models now support multi-functional tool heads in a single machine, including:

-

Vibrating knife

-

Rotary blade

-

V-cut tool

-

Creasing wheel

-

Milling tool

This multi-tool flexibility allows manufacturers to handle cutting, creasing, routing, perforating, and marking in one pass, reducing production time.

3. Enhanced High-Frequency Vibration Technology

The new oscillating knife technology offers higher vibration frequencies (up to 30,000–40,000 strokes per minute), delivering:

-

Smoother edges

-

Reduced wear on blades

-

Ability to cut denser or semi-rigid materials with precision

This advancement makes the machines more versatile across industries from packaging to automotive interior production.

4. Optical Recognition and CCD Camera Systems

With integrated CCD cameras and vision systems, vibrating knife machines can now:

-

Recognize printed graphics and contour lines automatically.

-

Align cutting paths with minimal human input.

-

Ensure perfect accuracy for industries like advertising, textile printing, and custom packaging.

5. Digital Connectivity and Industry 4.0 Integration

Modern vibrating knife cutting machines are built for smart factories. Key upgrades include:

-

Cloud-based monitoring of machine performance.

-

Predictive maintenance alerts to reduce downtime.

-

Remote operation and troubleshooting.

-

Seamless integration with ERP and MES systems.

This digital transformation enables manufacturers to scale faster while maintaining consistency and traceability in production.

Why Vibrating Knife Cutting Machines Are the Future

The combination of precision, eco-friendliness, and versatility makes vibrating knife technology one of the most sustainable and profitable cutting solutions for industries worldwide. From packaging prototypes to furniture, footwear, automotive interiors, and textiles, the demand for vibrating knife cutters will continue to grow in 2025 and beyond.

Conclusion

The 5 disruptive upgrades—AI-powered cutting, multi-tool integration, enhanced vibration technology, optical recognition, and Industry 4.0 connectivity—are reshaping the role of vibrating knife cutting machines in modern manufacturing.

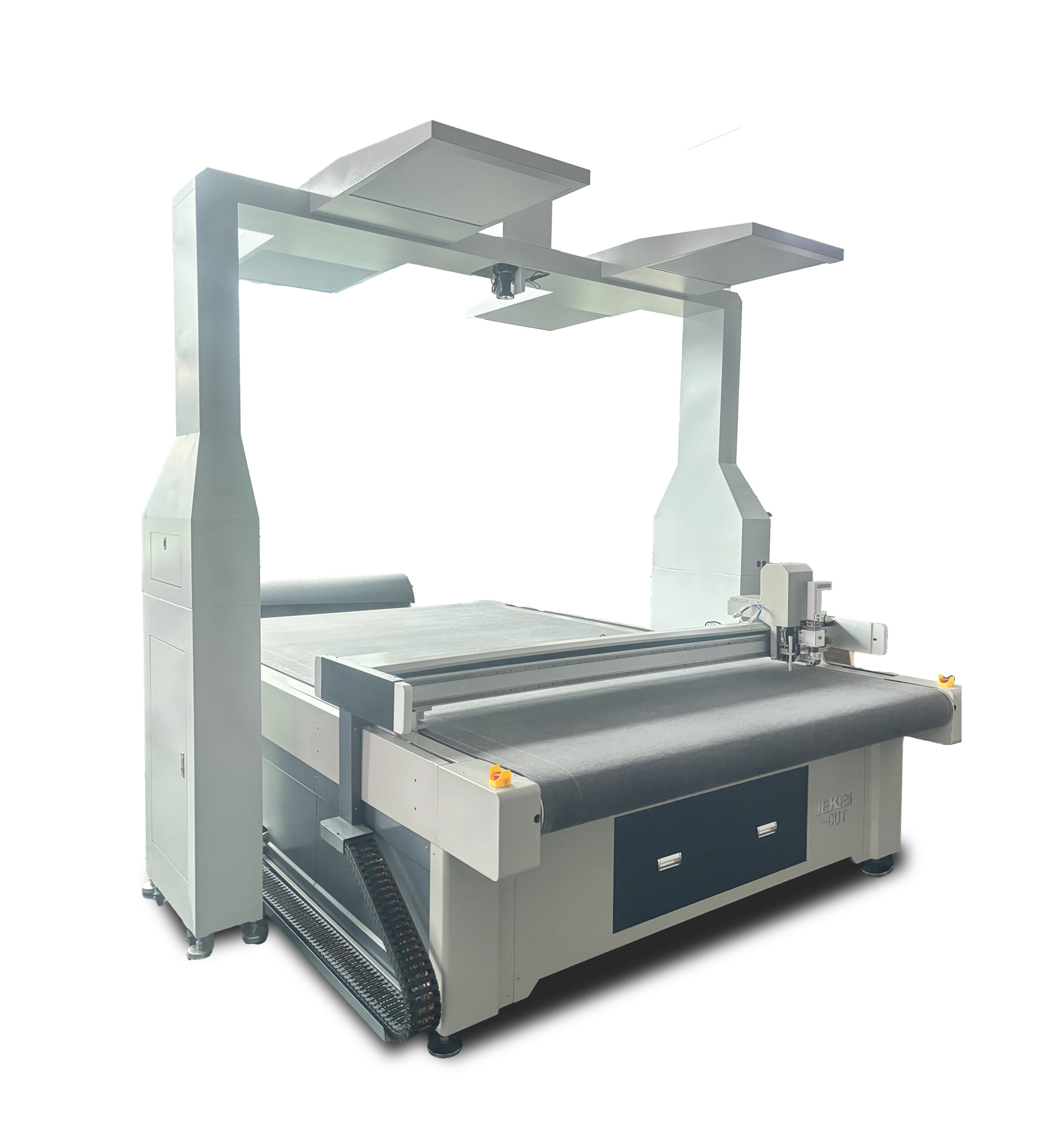

At JEKE CNC, we are committed to delivering next-generation CNC digital cutting solutions that help businesses reduce costs, increase flexibility, and achieve long-term growth.

Contact Us

Looking to upgrade to a 2025 vibrating knife cutting machine with the latest technology?

👉 Contact JEKE CNC today for free consultation, sample cutting tests, or the latest quotation.

📧 Email: alice_liu@jekecnc.com

📞 Phone/WhatsApp: +86-19065116408

🌐 Website: www.jekecnc.com