Flexible material CNC cutting scheme

Diversified customized cutting solutions to meet your needs!

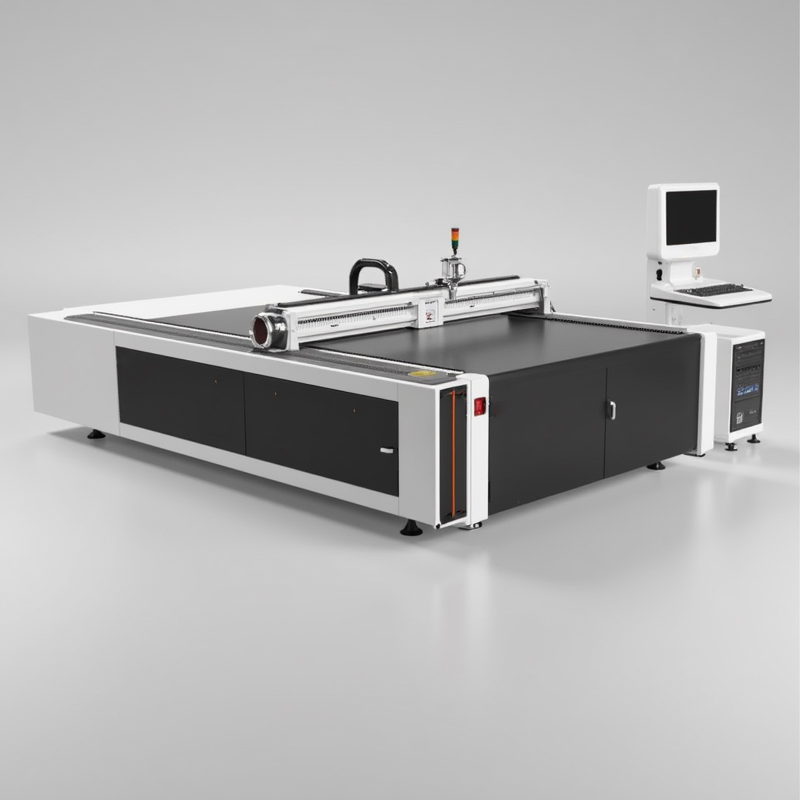

1.Cutting size: 2500 * 1600mm

2.Cutting speed: 1500-2000mm/s

3. Cutting thickness: 50-100mm

4. Adsorption system: Vacuum adsorption

5.Cutting accuracy: ± 0.01~0.05mm

6. Motor power: 7-13KW

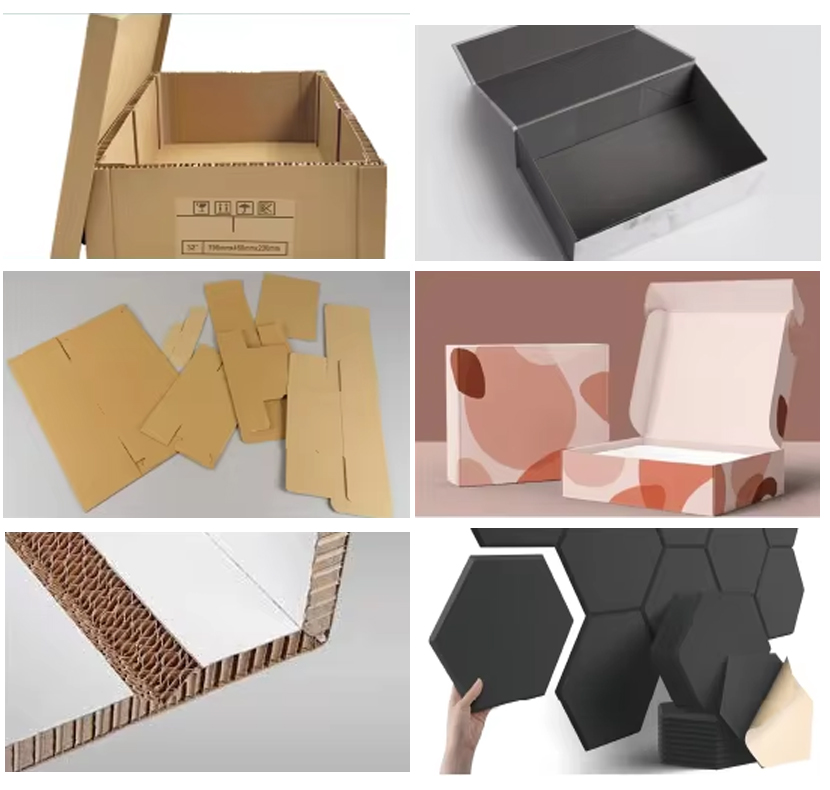

7. Flexible material cutting: corrugated cardboard, honeycomb cardboard, white cardboard, grey cardboard, copperplate paper, cowhide cardboard …..

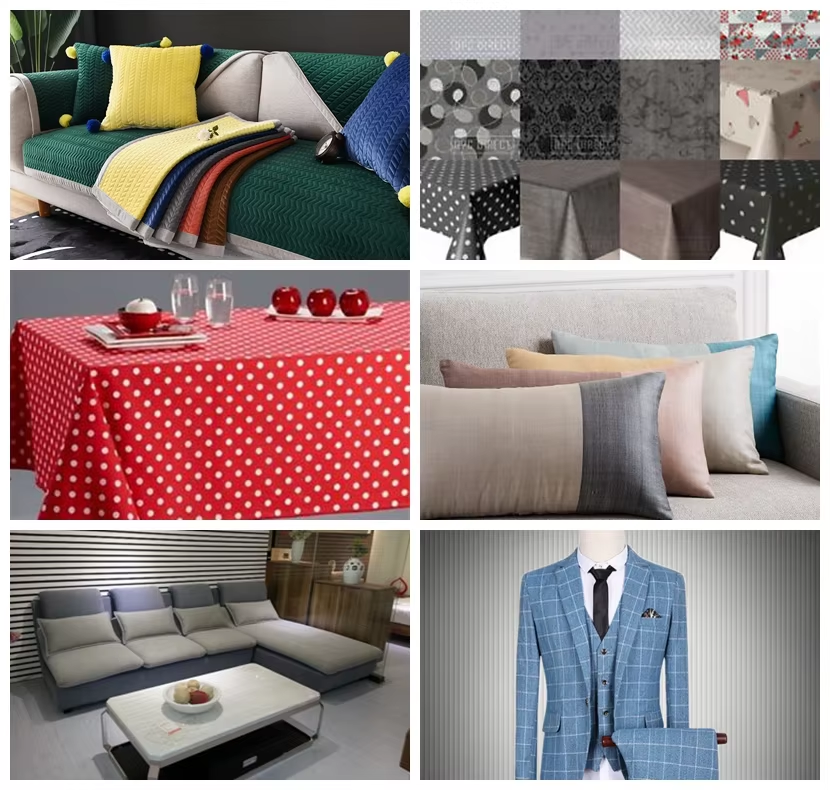

1.Cutting size: 2500 * 1300mm

2.Cutting speed: 1500-2000mm/s

3. Cutting thickness: 50-100mm

4. Adsorption system: Vacuum adsorption

5.Cutting accuracy: ± 0.01~0.05mm

6. Motor power: 10KW

7. Flexible material cutting: Cotton, linen, Oxford cloth, canvas, non-woven fabric, medical fabric, automotive interior fabric,Glass Fiber Cloth, PVC/PU Coated…..

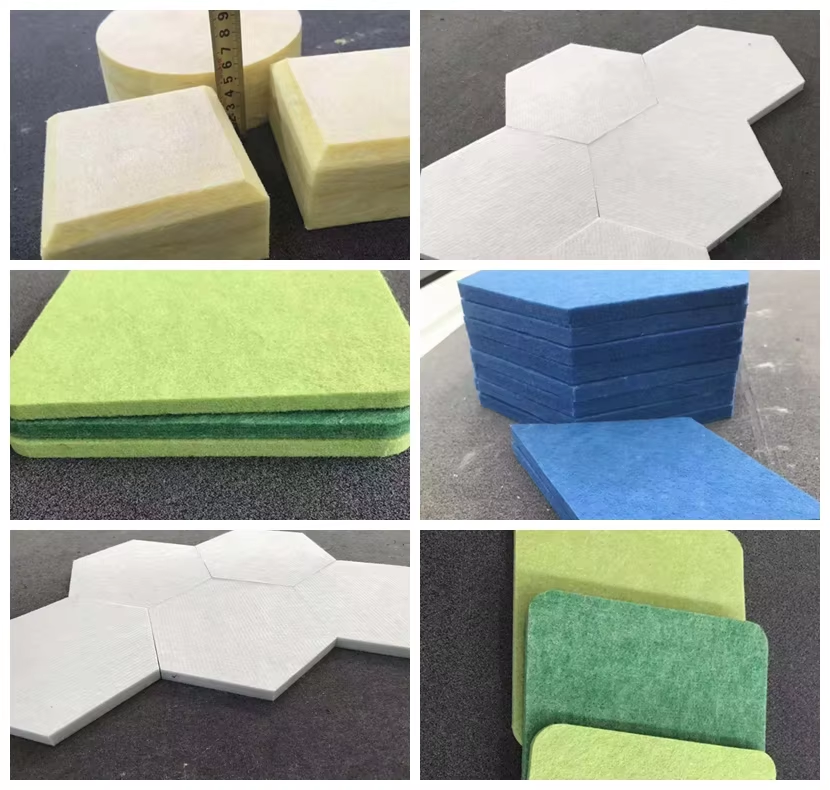

1.Cutting size: 2500 * 1900mm

2.Cutting speed: 1500-2000mm/s

3. Cutting thickness: 50-100mm

4. Adsorption system: Vacuum adsorption

5.Cutting accuracy: ± 0.01~0.05mm

6. Motor power: 13KW

7. Flexible material cutting: Floor mats, door mats, carpet mats, tablecloths, curtains, sunshade materials, insoles, shoe materials EVA, soft film …..

✅ Top 15 Commonly Used Materials for CNC Oscillating Knife Cutting

| Material Name | Industry | Thickness Range | Key Features |

|---|---|---|---|

| EVA Foam | Packaging / Footwear | 1–100mm | Excellent elasticity and shock absorption |

| EPE Foam (Pearl Cotton) | Packaging | 1–50mm | Lightweight, cushioning, eco-friendly |

| Oxford Fabric | Apparel / Bags | 0.3–1.5mm | Waterproof, wear-resistant |

| Non-woven Fabric | Medical / Apparel | 0.2–1mm | Cost-effective, soft texture |

| PVC Foam | Industrial | 2–20mm | Good sealing and resilience |

| Synthetic Leather (PU/PVC) | Apparel / Footwear | 0.5–3mm | Flexible and easy to shape |

| Honeycomb Board | Packaging | 10–50mm | Lightweight, high strength |

| KT Board | Advertising | 5–10mm | Foam core board, easy to cut |

| Lightbox Fabric | Advertising | 0.3–0.8mm | Soft, tensile, suitable for UV printing |

| Fiberglass Cloth | Industrial | 0.3–2mm | Heat-resistant and flame-retardant |

| Corrugated Board | Packaging | Single to triple flute | Ideal for express and custom packaging |

Sample display of cutting materials

Become our distributor

Why is CNC vibration knife cutting machine the future of flexible material cutting?

CNC Cardboard Cutting Machine Application

The cardboard box cutting machine is a newly designed carton box sample making system. The cardboard knife cutting machine has perfect work, high cut speed, and cut precision, and it’s easy to operate.

Cardboard cutter machine makes cutting, creasing, degree cutting, and tracing edge cutting available in one machine. It could meet sample making or small batch product of the packaging company.

The corrugated board cutting machine can cut cardboard, corrugated board, chipboard, foam board, plastic board, leather, cloth, honeycomb board, KT board and etc. We have a good reputation in markets of package, print, die cutting, gasket, sign industries, leather, textile, foam, rubber, etc.

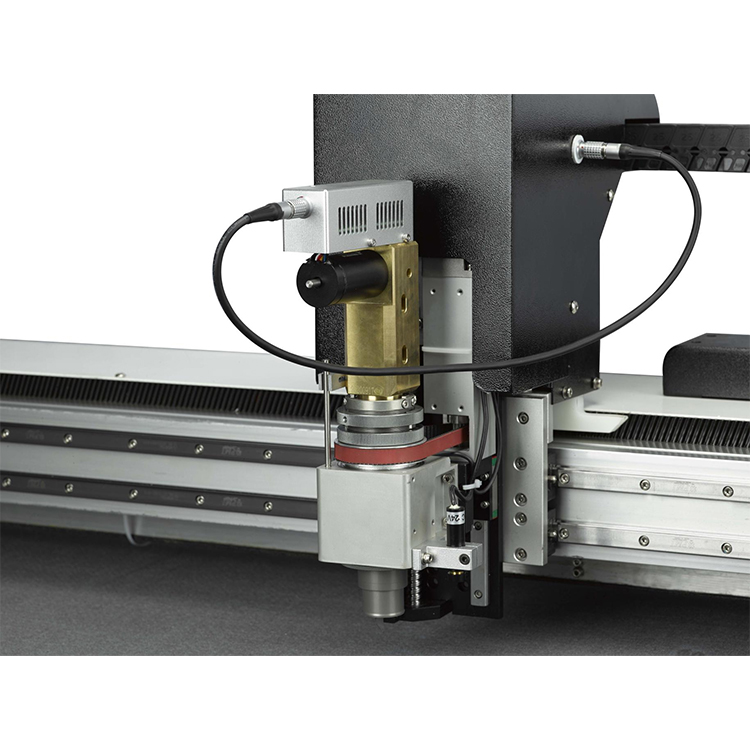

Key components of CNC cutting machine

Assemble various high-precision components to achieve military grade quality

Knife head module

Silk sliding gantry

Inovance servo motor

Strong flow fan

ccd camera

Cellular station

Interested To Be An Agent?

Provide CNC cutting raw materials

We can provide you with matching raw materials, cutting tools, consumables, felt, as well as comprehensive after-sales service and technical support.

corrugated paper

EVA Foam

Leather material

Cloth fabric

Quality Assurance

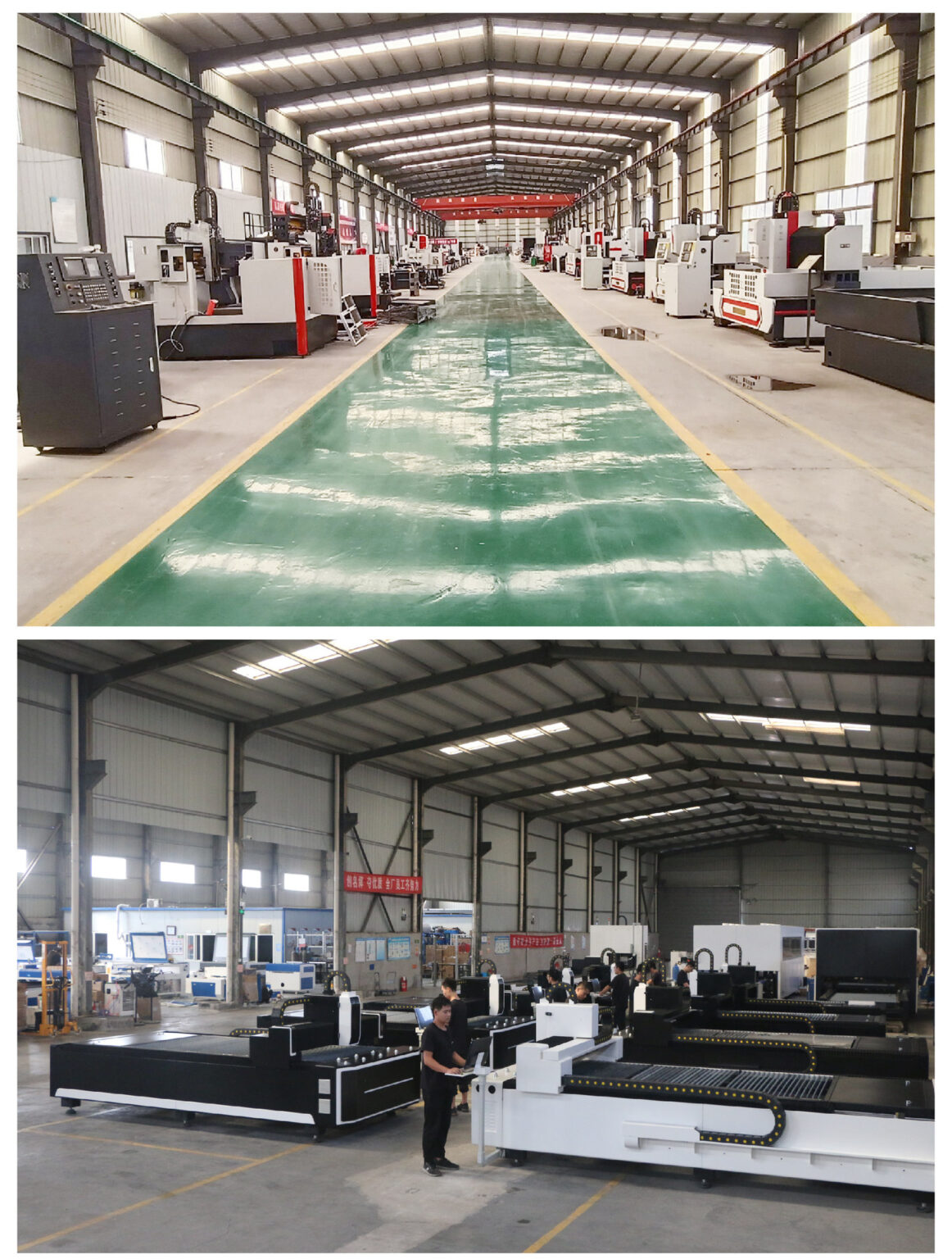

The attention to detail covers all aspects from material procurement to mass production. To create the most perfect CNC cutting machinery for your enterprise.

Our factory holds BSCI certification, operating under ISO9001 standards. Rigorous inspections encompass 100% mass production to ensure error-free wholesale orders. Internal QC teams and third-party inspectors reinforce mass production quality.

As a highly respected printing equipment manufacturer in China, we understand the importance of your technical needs and prioritize quality. Our CNC cutting machine has passed UL, OCE, ROHS and other certifications. Quality assurance is always the most important.

Our CNC cutting machine uses the most advanced CNC technology by 2025. Comprehensive performance cutting can improve ultimate cutting accuracy and efficiency.

All Services We Offer

We provide everything for CNC cutting, including:

💡 Professional Support

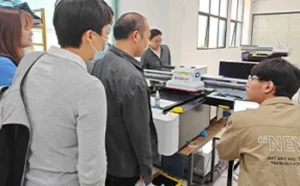

✔ Free online training & on-site guidance

✔ Global after-sales service & paid local support

🚀 Innovation & Cost Savings

✔ Lifetime machine upgrades

✔ Factory-direct sales – no middleman, lower costs

🌍 20+ Years of Import & Export Expertise

✔ Hassle-free import/export services

🔹 Your one-stop CNC cutting solution – Contact us today! 🚀

Interested To Be An Agent?

Customers from over 50 countries around the world trust us

📢 Customer Testimonials: Real Success with Our CNC Oscillating Knife Cutting Machine

Here are 5 real customer reviews from businesses that transformed their production with our CNC oscillating knife cutting solutions:

1️⃣ 📦 Custom Packaging Manufacturer (USA)

✅ Before: Manual die-cutting limited their ability to prototype quickly and precisely.

✅ After: Adopted our CNC vibrating knife cutter for precise, mold-free sample making of corrugated and honeycomb cardboard.

🗣 “This machine has revolutionized our sample production. No more waiting on dies—we go from design to cut in minutes!”

2️⃣ 👞 Footwear Materials Supplier (Brazil)

✅ Before: Difficulty cutting complex shoe insole patterns from EVA and foam with consistency.

✅ After: Uses our cutter for smooth, accurate, and repeatable EVA and PU foam cutting.

🗣 “Cuts thick EVA and soft foam like butter. The precision is top-notch, and it saves us material with every cut.”

3️⃣ 👜 Luxury Leather Goods Workshop (Italy)

✅ Before: Hand-cut leather caused uneven edges and low efficiency.

✅ After: Now achieves clean, repeatable cuts on genuine leather and PU with automated tooling.

🗣 “The edge quality is superb. We produce more, faster, and the cuts are consistent every time—even with intricate shapes!”

4️⃣ 👗 Textile & Apparel Factory (Vietnam)

✅ Before: Manual cutting of fabrics was labor-intensive and error-prone.

✅ After: Integrated our CNC cutting system to handle cotton, nylon, and laminated fabrics with vacuum hold-down.

🗣 “The cutting is clean, accurate, and fast. We’ve cut down fabric waste by 30% and increased our daily output significantly!”

5️⃣ 🎯 Multi-Material Prototyping Studio (UAE)

✅ Before: Needed one machine to cut a range of materials from cardboard to fabric to foam.

✅ After: Our machine became their go-to for versatile cutting of small-batch, custom jobs.

🗣 “It’s like having five machines in one! We cut cardboard, leather, EVA, and fabric—all with perfect precision and zero tool change hassle.”

Get started on your best CNC cutting buying journey now. We would welcome a call or email from you!

We provide you with all the support!

Reply within 2 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

+8619065116408

amanda_ye@jekecnc.com