We believe we can assist you in solving challenges related to CNC machinery.

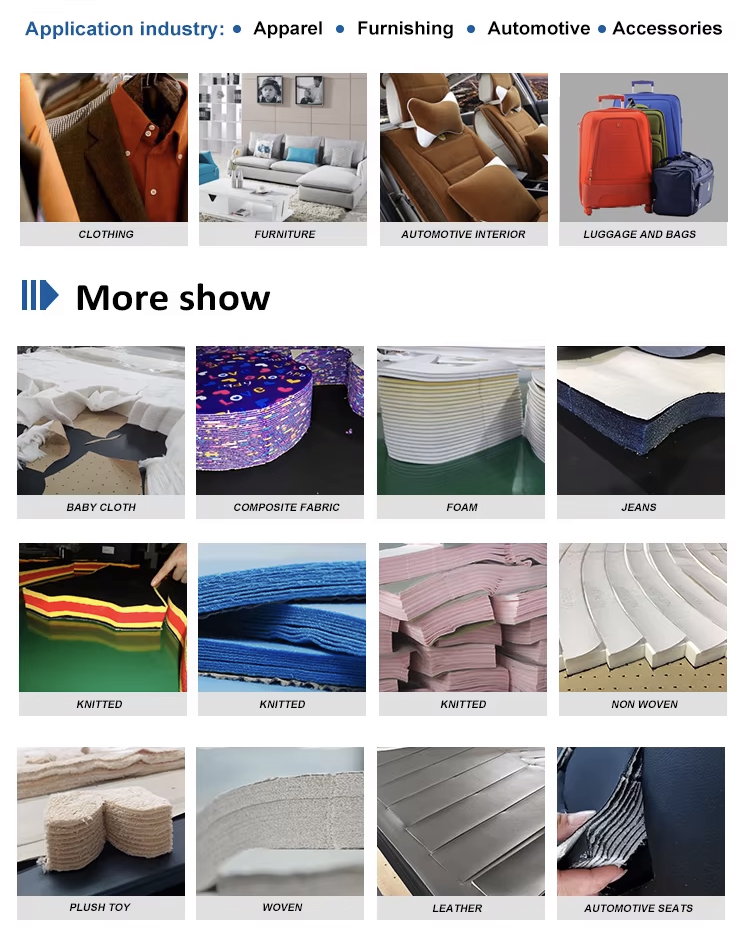

The JK-1725 Fully Automatic Computerized Cutting Bed by JEKE is designed to meet the needs of the textile and garment industry with precision, efficiency, and flexibility. This cutting-edge CNC solution is capable of high-speed multi-layer cutting, offering enhanced functionality for large-scale production, particularly for apparel manufacturing. Whether you are cutting woven fabrics, knits, or technical textiles, the JK-1725 provides a reliable solution for optimizing your production workflow.

| Parameter | Details |

|---|---|

| Cutting Height | 3cm / 5cm / 7cm / 9cm (After vacuum sorption) |

| Cutting Window Length | No limitation |

| Cutting Window Width | ≤ fabric width |

| Working Width (Y) | 1700mm / 2000mm / 2200mm / Customizable |

| Table Width | 1800mm / 2100mm / 2300mm / Customizable |

| Nominal Working Length (X) | 2500mm (Standard) / 3300mm (Optional) |

| Electricity | Three-phase 380V, 50~60Hz |

| Rated Power Consumption | 18kW |

| Cutting Method | Up and down repeated cutting |

| CNC Motor Driver | TECO Taiwan / Panasonic Japan (Optional) |

| Pneumatic Motor Driver | SMC Japan |

| Deceleration System | Planetary Gear |

| Servo Motors (X, Y, Z, T) | 4 sets, 400W-2KW |

| Compressed Air | 0.55Mpa, 160L/min |

| Cutting Speed | Max. 60,000mm/min |

| Acceleration | 0.6~0.8g (N/Kg) |

| Noise Level | < 75 dBA |

| Functional Temperature | -10°C to 45°C |

| Humidity | 5-95% (Non-condensing) |

| Dimensions (L/W/H) | 5.35m / 2.45m / 1.5m |

| Weight | 2100kg |

Customization options are available. Specifications are subject to change without prior notice.

1. Can the JK-1725 cut different types of fabrics?

Yes, it can cut various fabrics, including woven, knitted, and technical textiles.

2. What is the cutting height range of the JK-1725?

The cutting height can be adjusted to 3cm, 5cm, 7cm, or 9cm based on the material thickness.

3. How fast can the JK-1725 cut?

The cutting speed can reach up to 60,000mm/min, making it suitable for high-volume production.

4. What is the power consumption of the JK-1725?

The machine has a rated power consumption of 18kW.

5. Does JEKE offer customization for the JK-1725?

Yes, JEKE offers customizable specifications, including working width, table dimensions, and cutting length, to meet your unique production needs.

The JK-1725 Fully Automatic Computerized Cutting Bed by JEKE is an ideal solution for high-volume garment production, offering advanced cutting technology, precision, and versatility. Whether you’re cutting fabric for custom fashion or mass production, this machine guarantees enhanced productivity, accuracy, and efficiency. Contact JEKE today to learn more about how this cutting-edge technology can optimize your production process.

If you have any other questions about CNC equipment, you can also contact us

If you have CNC needs or concerns, please feel free to contact our industry experts at any time. We are always ready to answer any questions for you!

The entire process from planning to delivery was very smooth and satisfactory. The JEKE team responded quickly and their CNC quality is top-notch! They kept their promises and exceeded expectations. We look forward to establishing a long-term partnership with them

This insightful exploration delves into the latest developments in CNC cutting technology, artificial intelligence, and automation.

amanda_ye@jekecnc.com

+86 13532668516

We will arrange for a specialist to contact you immediately.