We believe we can assist you in solving challenges related to CNC machinery.

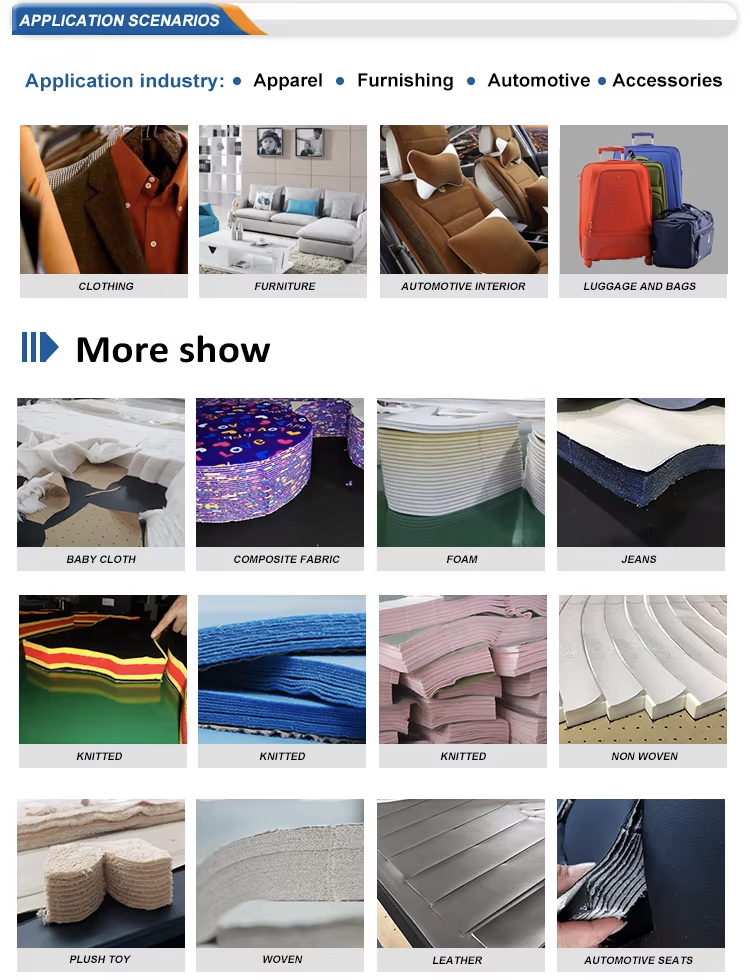

JK-1825 Automatic Fabric Cutter series automated fabric cutting machine is a type of machinery that is designed to cut fabric materials automatically, without the need for manual labor. These machines use computer-controlled cutting systems to cut fabrics into precise shapes and sizes, according to pre-programmed designs and patterns.

The JK-1825 Automatic Fabric Cutter is the latest innovation by JEKE, designed to redefine the standards of precision, efficiency, and versatility in mass fabric cutting. This advanced machine is engineered to cater to diverse production needs while ensuring minimal waste and impeccable quality. Whether you are a small business or a large-scale manufacturer, the JK-1825 is your reliable partner for cutting excellence.

| Feature | Details |

|---|---|

| Max Cutting Height | 6 cm / 9 cm (after vacuum absorption) |

| Cutting Window Length | No limitation |

| Cutting Window Width | No wider than the fabric width |

| Working Width (Y) | 1700mm / 2000mm / 2200mm / Customized |

| Normal Working Length (X) | 2500mm Standard / 3300mm Lengthen Optional |

| Electricity | Three phase 380V, 50~60Hz |

| Power Consumption | 18KW max |

| CAD & CAM Connect Way | Ethernet communication / USB Flash memory |

| Max Speed of Blade Working | 6000rpm/min |

| Compressed Air | 0.55Mpa 160L/min |

| Max Cutting Speed | 60000mm/min |

| Acceleration | 0.6~0.8g (N/Kg) |

| Cutting Accuracy | ≤ ±1mm |

| Noise Level | < 75 dbA |

Test Data:

Q1: What fabrics can the JK-1825 cut? A1: The JK-1825 is versatile and capable of cutting various fabrics, including cotton, polyester, silk, denim, and technical textiles.

Q2: Can the cutting dimensions be customized? A2: Yes, the working width and length can be customized to suit your production needs.

Q3: Is the machine compatible with all CAD software? A3: The machine supports CAD software integration via Ethernet or USB, ensuring compatibility with most industry-standard programs.

Q4: How do I maintain cutting accuracy? A4: Regular maintenance and proper setup (e.g., blade height and speed adjustments) ensure optimal cutting accuracy.

Q5: Does JEKE provide training? A5: Yes, JEKE offers comprehensive training and technical support to help you maximize the machine’s potential.

The JK-1825 Automatic Fabric Cutter is the ultimate solution for mass fabric cutting, combining precision, efficiency, and versatility. Its advanced features and robust performance make it a vital asset for modern textile manufacturing. Trust JEKE to deliver not just cutting machines but complete solutions for your production challenges.

If you have CNC needs or concerns, please feel free to contact our industry experts at any time. We are always ready to answer any questions for you!

The entire process from planning to delivery was very smooth and satisfactory. The JEKE team responded quickly and their CNC quality is top-notch! They kept their promises and exceeded expectations. We look forward to establishing a long-term partnership with them

This insightful exploration delves into the latest developments in CNC cutting technology, artificial intelligence, and automation.

amanda_ye@jekecnc.com

+86 13532668516

We will arrange for a specialist to contact you immediately.